If you’re serious about producing chocolate—whether bonbons, bars, coatings, or enrobed items—the right chocolate tempering machine can dramatically improve your workflow and results. From capacity and automation to cleaning and voltage, here’s what to consider when making your choice.

🔍 1. Assess Your Production Volume & Growth Plans

Start by identifying your current production needs and where you expect to be within the next one to three years. A machine that’s too small will slow you down, while an oversized one may be unnecessarily costly or take up too much space.

- Small-batch artisans: A compact tabletop model handling 3–5 kg is ideal.

- Growing chocolateries: Consider mid-size or automatic machines with 10–20 kg capacity.

- Large producers: Go for high-capacity automatic systems designed for continuous operation.

🔧 2. Manual vs. Automatic Operation

Tempering machines come in three levels of automation: manual, semi-automatic, and fully automatic. Manual models require hands-on control, while automatic ones handle heating, cooling, and agitation for you.

- Manual: Lower cost, suitable for artisans who prefer full control.

- Semi-automatic: Great balance between flexibility and efficiency.

- Automatic: Consistent results, perfect for volume production or multi-operator environments.

📐 3. Capacity, Tank Size & Throughput

Evaluate how much chocolate you need to be melted and tempered simultaneously. The tank capacity (in kg) determines batch size, while throughput (kg/hour) indicates how fast the machine can cycle through production.

Tip: Always choose a machine that can comfortably handle at least 20–30% more than your current daily output to allow for growth.

⚡ 4. Electrical Setup & Compatibility

For Canadian and U.S. operations, ensure your tempering machine is configured for 110 V / 60 Hz. Using 230 V European models often requires transformers or additional wiring, which adds cost and complexity. Confirm plug type and certification (CSA or UL) for safe operation.

🧼 5. Build Quality, Materials & Cleanability

Chocolate can be messy! Choose a model built with food-grade stainless steel, smooth interior surfaces, and removable components. Easy-to-clean designs save hours of maintenance and reduce contamination risk. Look for machines with detachable tanks or augers for effortless cleaning.

📊 6. Features & Controls

Modern tempering machines offer smart controls to simplify your process. Look for:

- Digital temperature display and automatic control

- Preset programs for dark, milk, and white chocolate

- Air or water cooling for precision tempering

- Removable screw or bowl for easy cleaning

- Optional vibrating tables or dosing heads for filling molds

💲 7. Budget, Service & Support

Prices vary depending on brand, capacity, and automation. Always consider the total cost of ownership—shipping, warranty, parts availability, and local support. Buying from a trusted North American distributor like Zucchero Canada ensures easier service and warranty coverage.

✅ 8. Match the Machine to Your Use Case

| Operation Type | Recommended Machine | Capacity |

|---|---|---|

| Artisan / Hobbyist | Tabletop MiniTemper (Pavoni Italia) | 3 kg |

| Boutique Chocolaterie | Pomati T5 or Easy Temp M1705 | 5 kg – 10 kg |

| Commercial Production | Chocolate World M1250 or larger | 24 kg + |

🏁 Final Thoughts

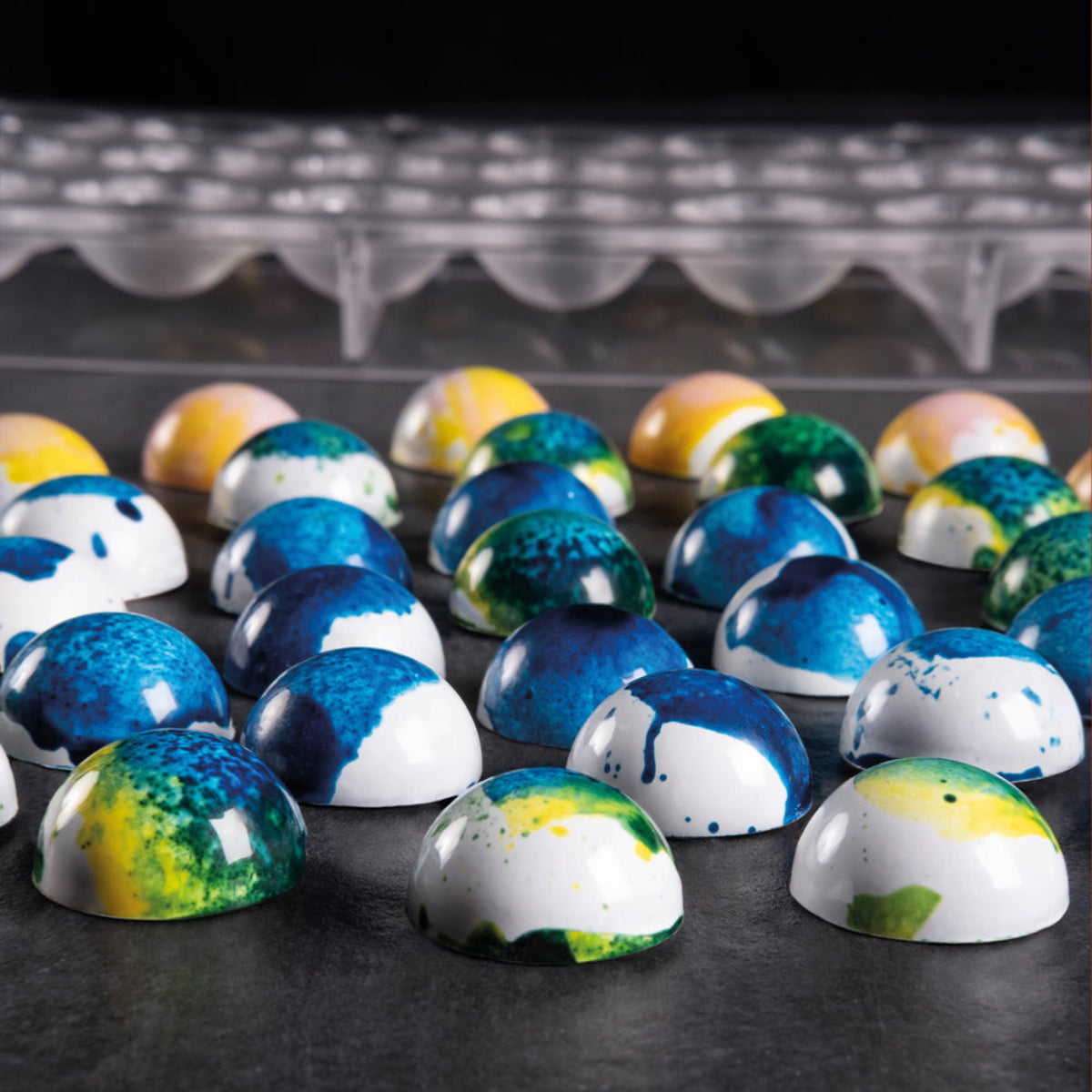

Choosing the right chocolate tempering machine is an investment in precision, quality, and efficiency. Prioritize reliability, cleaning ease, and power compatibility to make your workflow smoother. Whether you’re starting small or scaling up, the right equipment will help you craft flawless, glossy chocolates every time.

Discover the full selection of professional chocolate tempering machines at Zucchero Canada — your trusted source for premium pastry and chocolate equipment across North America.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.