The world of chocolate moulds is both diverse and specialized, offering confectioners countless options for creating beautiful and functional chocolate creations. Whether you're a professional chocolatier or home enthusiast, understanding the different types of moulds, their materials, and applications can significantly impact your chocolate-making success. This comprehensive review explores everything you need to know about chocolate moulds.

Understanding Chocolate Mould Materials

Chocolate moulds come in several materials, each with distinct properties that affect everything from chocolate release to longevity.

Polycarbonate Moulds

Polycarbonate moulds represent the gold standard in professional chocolate making. These rigid, clear plastic moulds offer exceptional durability and remarkable surface clarity that transfers to your chocolates.

When working with polycarbonate moulds, you'll notice they produce chocolates with an exceptional shine. This happens because the perfectly smooth surface of the polycarbonate creates a mirrored effect on the chocolate as it sets. The rigidity of these moulds also ensures precise, consistent shapes without warping, even after hundreds of uses.

The temperature stability of polycarbonate is particularly impressive—they can withstand temperatures from -20°C to 120°C without degrading, making them perfect for both refrigeration and working with warm chocolate. This temperature resistance means you can use them for generations if properly maintained.

Professional chocolatiers often invest in polycarbonate moulds because, despite their higher initial cost (ranging from $15-$50 per mould), the long-term value is undeniable. Many polycarbonate moulds last 10+ years in commercial settings.

Silicone Moulds

Silicone moulds have revolutionized home chocolate making with their flexibility and ease of use. Unlike rigid moulds, silicone allows you to simply flex the mould to release the chocolate, which is particularly helpful for intricate designs.

The temperature range for silicone is impressive, typically from -40°C to 230°C, making these moulds versatile enough for chocolate tempering and even baking applications. This versatility means your chocolate silicone moulds can double as bakeware for small pastries or frozen desserts.

While silicone doesn't produce chocolates with quite the same high gloss as polycarbonate, the finished chocolates still have an appealing satin finish. The slight flexibility of silicone also means designs can be more intricate with undercuts that would be impossible to remove from rigid moulds.

One consideration with silicone is its tendency to absorb odors over time, especially when used with strongly flavored ingredients like citrus oils or spices. To prevent flavor transfer between batches, it's wise to dedicate specific moulds to particular flavor profiles.

PET/PVC Moulds

PET (polyethylene terephthalate) and PVC (polyvinyl chloride) moulds occupy the entry-level segment of chocolate moulds. These lightweight plastic moulds are generally inexpensive and widely available.

These moulds typically last for 10-30 uses before showing signs of wear, making them ideal for beginners, seasonal projects, or testing new designs before investing in higher-quality moulds. Their temperature range is more limited than professional-grade materials, usually safe from 0°C to about 60°C.

While PET/PVC moulds produce chocolates with a respectable shine, they don't quite match the mirror-like finish of polycarbonate. The trade-off comes in affordability—most PET/PVC moulds cost between $3-$10, making them accessible for hobbyists.

Mould Types and Applications

The world of chocolate moulds extends far beyond material considerations, with specialized designs for every chocolate application imaginable.

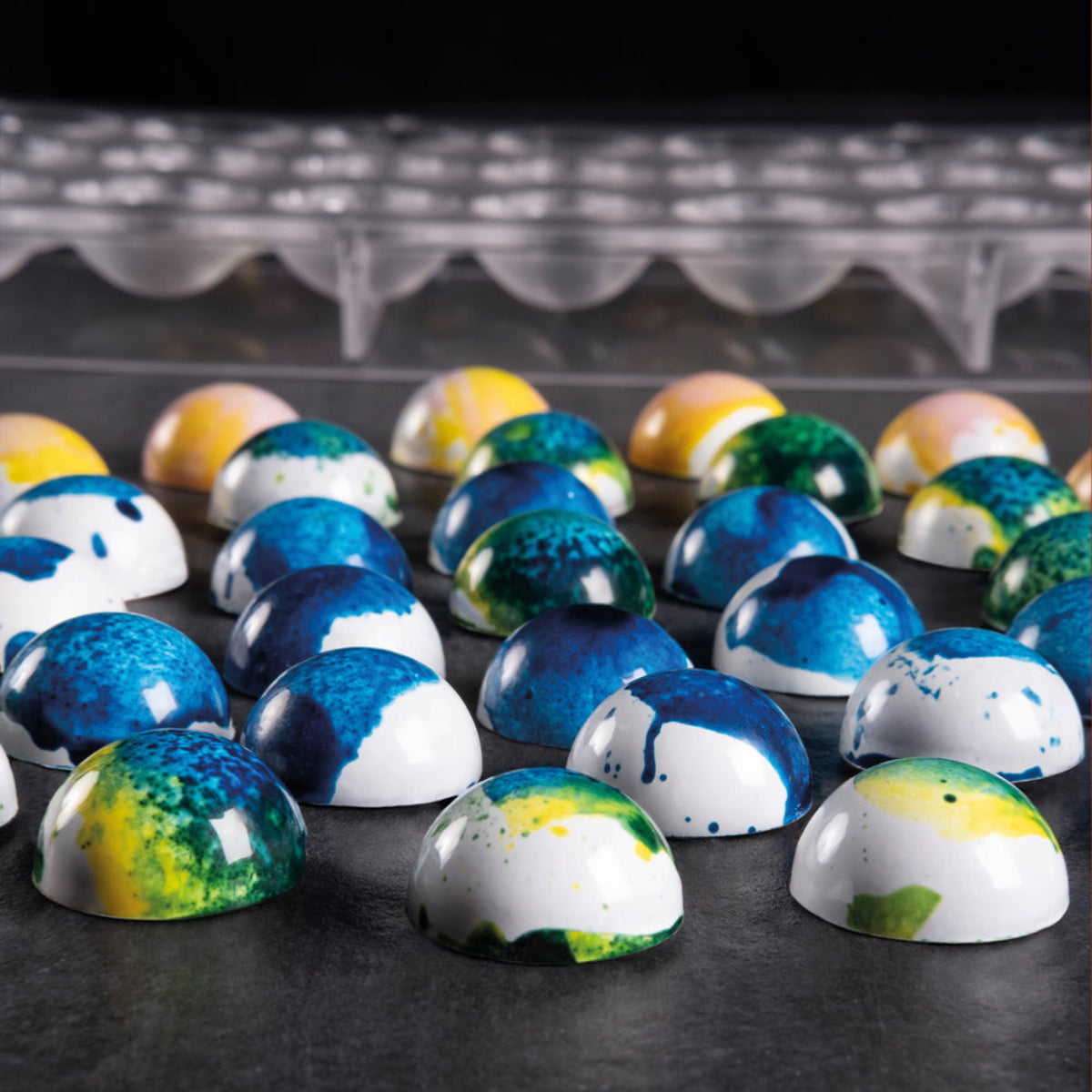

Bonbon/Praline Moulds

Bonbon moulds typically feature small cavities (15-30mm) designed to create shell-based filled chocolates. These moulds are engineered with specific features that facilitate the shell-making process:

The cavity shapes often include a wider opening that tapers to a narrower base, which helps when coating the mould with chocolate. This design allows excess chocolate to drain cleanly when the mould is inverted during the shell-making process.

Professional bonbon moulds typically contain 24-35 cavities per mould, allowing efficient production. The spacing between cavities is carefully designed to provide structural integrity while maximizing production capacity.

When selecting bonbon moulds, consider the depth-to-width ratio carefully. Deeper moulds with narrower openings create elegant, tall bonbons but can be more challenging for beginners as they require more precise chocolate handling to achieve even shell thickness.

Tablet/Bar Moulds

Chocolate bar moulds range from simple rectangular shapes to elaborate segmented designs. Professional bar moulds often incorporate clever engineering features:

Break lines (thin indentations) are strategically placed to allow clean snapping of the finished chocolate bar. The depth and angle of these break lines determine how easily the bar will snap—typically 1/3 to 1/2 the depth of the bar thickness is ideal.

Edge detailing in quality bar moulds often includes a slight bevel or rounded edge that not only looks professional but also reduces the risk of edge chipping during unmoulding.

Bar moulds come in standard sizes ranging from mini bars (30-50g) to full-sized bars (100-200g). The cavity depth typically ranges from 7mm for delicate bars to 12mm for chunkier styles.

Figurine/3D Moulds

Three-dimensional chocolate creations require specialized moulds that come in two main varieties:

Two-piece moulds consist of front and back sections that clamp together, creating a hollow center. The joining technique is crucial—look for moulds with precise alignment pins or channels that allow excess chocolate to escape cleanly when the mould halves are pressed together.

Seamless one-piece moulds create hollow figures with a single opening at the bottom. These are typically made from flexible silicone with carefully designed draw angles (the slope of the sides) that allow the chocolate to release without damage.

The wall thickness of 3D moulds is particularly important—professional moulds create chocolate walls between 2.5-4mm thick, providing sufficient strength while ensuring the chocolate remains pleasantly edible.

Specialty Moulds

Beyond the standard categories, specialty moulds cater to specific techniques and presentations:

Transfer sheet moulds feature a flat base designed to incorporate printed cocoa butter designs. The depth is typically 2-3mm, providing just enough thickness for structural integrity while showcasing the transfer design.

Magnetic moulds represent an innovation with embedded magnets in the form, allowing chocolate decorations to adhere to metal surfaces—ideal for modern plated dessert presentations.

Structural component moulds create interlocking chocolate pieces that can be assembled into larger structures. These require precision engineering with tolerances of less than 0.5mm to ensure components fit together properly.

Evaluating Mould Quality

Not all chocolate moulds are created equal. Understanding quality indicators helps make informed purchasing decisions.

Surface Finish

The interior surface finish of a chocolate mould directly translates to the exterior finish of your chocolates. Professional-grade moulds undergo multiple polishing processes to achieve a mirror-like interior surface.

In polycarbonate moulds, look for a completely transparent, glass-like interior surface without any frosting or haziness. When examined under bright light, you should not see any fine scratches or tool marks from the manufacturing process.

Silicone moulds should have a uniform, slightly satiny interior finish without any bubbles, pinholes, or texture variations that would transfer to the chocolate surface.

Design Precision

Quality moulds display exceptional attention to detail in their design execution:

Sharp definition of fine details indicates precision in the mould manufacturing process. Examine intricate areas like texture patterns or fine lines to assess how cleanly they're executed.

Uniform wall thickness throughout the mould ensures even cooling and consistent chocolate quality. In cross-section, professional moulds maintain thickness consistency within 0.2mm.

Properly engineered draft angles (the slight taper of vertical surfaces) of approximately 2-5 degrees facilitate easy release of chocolates without distortion.

Durability Features

Several structural elements contribute to mould longevity:

Reinforced rims prevent warping during temperature changes and provide structural rigidity during handling. Professional moulds often feature thickened edges that are 1.5-2 times the thickness of the main body.

Quality polycarbonate moulds undergo stress-relieving heat treatments during manufacturing to prevent micro-cracks from developing over time with temperature fluctuations.

For silicone moulds, platinum-cured silicone (as opposed to peroxide-cured) offers superior heat stability and resistance to degradation, maintaining its properties through hundreds of use cycles.

Working with Different Mould Types

Each mould material and type requires specific handling techniques for optimal results.

Polycarbonate Techniques

Polycarbonate moulds benefit from particular preparation and handling:

Temperature conditioning is crucial—bring the mould to around 27-30°C (slightly below the working temperature of tempered chocolate) before filling. This prevents the chocolate from cooling too rapidly upon contact, which can lead to uneven crystallization and dull spots.

Cleaning requires gentle handling—use only soft cloths and mild, non-abrasive detergents. Never use alcohol-based cleaners as they can attack the polycarbonate surface, creating micro-scratches that will affect chocolate finish.

The unmoulding technique involves a precise temperature cycle: refrigerate filled moulds at 10-12°C for 10-15 minutes, then allow them to warm slightly before unmoulding. This creates a slight contraction of the chocolate that aids release.

Silicone Handling

Silicone moulds require their own specialized approach:

Pre-use conditioning is recommended—many professional chocolatiers "season" new silicone moulds by washing them with warm water and mild detergent, then applying a thin layer of cocoa butter that is allowed to set and then removed. This microfine residue improves release properties.

Temperature management differs from polycarbonate—silicone can be used at room temperature as it doesn't conduct heat as rapidly, preventing chocolate shock when filling.

For unmoulding, silicone allows a unique approach: start releasing from the edges by gently peeling back the silicone, then progressively work toward the center of the design. This controlled release prevents stress on delicate details.

Preventing Common Issues

Specific techniques help avoid frequent mould-related problems:

Air bubbles can be eliminated by proper tapping techniques—tap filled moulds on a rubber mat using a specific rhythm: three firm taps, rotate 90 degrees, three more taps, and so on to dislodge trapped air from all angles.

Incomplete filling of intricate details can be prevented by using a small artist's brush to push chocolate into detailed areas before filling the remainder of the cavity.

Release issues are often solved with proper temperature cycling—professional chocolatiers sometimes use the "thermal shock" technique, briefly placing the filled mould in the freezer for 60-90 seconds before returning to refrigerator temperature. This creates a micro-separation between mould and chocolate.

Leading Chocolate Mould Brands

The chocolate mould market features several distinguished manufacturers with different specialties.

Chocolate World

Belgium-based Chocolate World has established itself as the premier manufacturer of professional chocolate moulds. Their polycarbonate moulds are considered the industry standard for several reasons:

The manufacturing precision of Chocolate World moulds is exceptional, with dimensional tolerances maintained within 0.1mm across their product line. This precision ensures consistent results, especially important for shell thickness in bonbon production.

Their design library is extensive, with over 2,000 different mould designs ranging from classic to contemporary. Many top chocolatiers collaborate with Chocolate World to create signature moulds.

Durability is remarkable—many professional chocolatiers report using their Chocolate World moulds daily for over 15 years without significant degradation in performance or finish quality.

The price point reflects this quality, with most professional moulds ranging from $35-$75, representing a significant investment but delivering value through longevity and consistent results.

Martellato

Italian manufacturer Martellato offers an excellent balance of quality and value:

Their polycarbonate moulds feature slightly thicker construction than competitors (typically 2mm vs. 1.5mm), providing extra rigidity that professionals appreciate when handling large production volumes.

Martellato's design aesthetic tends toward classical Italian confectionery styles with elegant, refined shapes rather than trend-driven novelty designs.

Their magnetic mould system is particularly innovative, allowing chocolatiers to create decorative elements that can attach to metal presentation elements for modern plated desserts.

Price points are approximately 15-20% lower than Chocolate World while maintaining comparable quality standards, making them popular with small-to-medium production chocolatiers.

Pavoni

Italian manufacturer Pavoni focuses on artistic and sculptural chocolate applications:

Their Designer Collection features collaborations with renowned pastry chefs and chocolate artists, creating moulds that produce distinctive signature pieces.

Pavoni's microperforated polycarbonate moulds represent a technical innovation—microscopic texturing that enhances release properties while maintaining high gloss.

Their modular 3D systems allow chocolatiers to create large-scale showpieces from manageable components, with precisely engineered joining mechanisms.

The educational support Pavoni provides distinguishes them from competitors—each professional mould comes with detailed instructions and often video tutorials for achieving optimal results.

Cost Considerations and Investment Strategy

Developing a strategic approach to mould investment helps optimize both results and budget.

Cost-Benefit Analysis

When evaluating moulds, consider these factors beyond the initial price:

Production volume significantly impacts the value equation—a professional polycarbonate mould costing $50 that produces 5,000+ chocolates over its lifetime has a per-use cost of just $0.01, compared to a $5 PET mould that might last for 25 uses ($0.20 per use).

Design exclusivity carries both tangible and intangible value—signature moulds create distinctive products that can command premium pricing and build brand recognition.

Material efficiency varies between mould types—professional moulds with precision cavities typically waste less chocolate during production. The savings in expensive couverture can offset higher mould costs surprisingly quickly.

Building a Professional Collection

Chocolate professionals typically develop their mould collection strategically:

Core production moulds (bonbons, bars, seasonal staples) justify investment in the highest quality options, as these will be used continuously.

Seasonal and trend-driven designs might warrant mid-range options, balancing quality with the recognition that these designs have a limited commercial lifespan.

A typical professional starter collection for a boutique chocolate business includes 8-12 bonbon designs, 2-3 bar formats, and 3-4 seasonal specialty moulds, representing an investment of approximately $500-$800.

Mould Maintenance and Longevity

Proper care dramatically extends mould lifespan and maintains performance.

Cleaning and Storage

Professional mould maintenance follows specific protocols:

The cleaning regimen for polycarbonate moulds should avoid abrasives and harsh chemicals—warm water (40-45°C) with mild detergent is sufficient. For stubborn chocolate residue, a brief soak (no more than 5 minutes) followed by gentle wiping is recommended over scrubbing.

Storage conditions significantly impact longevity—professional chocolatiers store polycarbonate moulds flat (never stacked without protection) in a temperature-stable environment away from direct sunlight. Many use dedicated cabinet systems with individual slots to prevent contact between moulds.

Dust protection is important for maintaining surface finish—covering moulds with acid-free tissue or specialized mould covers prevents dust accumulation that can transfer to chocolates.

Addressing Common Damage

Even with careful handling, moulds may require maintenance:

Surface restoration techniques can rejuvenate minor scratches on polycarbonate—professional mould polishing compounds applied with microfiber in circular motions can often restore satisfactory shine.

Edge damage on polycarbonate moulds can sometimes be repaired using careful application of heat to "reset" the material structure. This is a specialized technique best performed by experienced professionals.

Silicone mould lifespan can be extended by avoiding oils and fats in cleaning solutions, as these can be absorbed by the silicone and affect release properties.

Innovation in Chocolate Mould Technology

The chocolate mould industry continues to evolve with new technologies.

Recent Developments

Several innovations are changing chocolate mould capabilities:

Computer-designed texture mapping allows unprecedented surface detail, creating moulds with textures as fine as 0.3mm that transfer perfectly to chocolate surfaces.

Temperature-responsive materials in some new silicone formulations create "active release" properties—slightly contracting when cooled to facilitate easier chocolate removal.

Antimicrobial surface treatments are beginning to appear in professional moulds, incorporating food-safe compounds that inhibit bacterial growth in microscopic surface imperfections.

Future Trends

The horizon for chocolate mould technology includes several promising developments:

Custom-printed moulds using industrial 3D printing technologies are becoming more accessible, allowing chocolatiers to design completely personalized forms without the high costs of traditional mould fabrication.

Interactive elements are emerging in specialty moulds—including QR code impressions that can be molded directly into chocolate surfaces, linking physical products to digital content.

Sustainable materials research is advancing, with plant-based polymers being developed as alternatives to petroleum-derived plastics for eco-conscious chocolate production.

Conclusion

Chocolate moulds represent a fascinating intersection of culinary art, materials science, and precision engineering. Understanding the nuances of different mould types, materials, and brands empowers both professionals and enthusiasts to create exceptional chocolate products.

When selecting chocolate moulds, consider your specific application, production volume, quality requirements, and budget to make informed decisions. With proper selection, use, and maintenance, quality chocolate moulds become valuable tools that can elevate your chocolate creations for years to come.

Whether you're producing professional bonbons, crafting seasonal figurines, or exploring chocolate artistry, the right moulds make all the difference between adequate results and truly exceptional chocolate work.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.