Choosing the right chocolate for melting dramatically impacts your final results—from smooth, glossy coatings to perfectly molded decorations. Understanding what chocolate is best for melting helps you select appropriate types for specific applications, whether you're dipping strawberries, creating chocolate decorations, or coating candies. This comprehensive guide explores different chocolate for melting options, from professional couverture to convenient candy melts, helping you make informed decisions that ensure consistent, delicious results every time.

Understanding Chocolate Composition for Melting

The secret to successful melting chocolate lies in understanding its composition and how different ingredients affect melting behavior.

Cocoa Butter's Critical Role: Real chocolate contains cocoa butter—a natural fat that melts smoothly and creates glossy, stable results. Higher cocoa butter content (32-39%) produces superior melting properties and professional appearance. This is why premium fine chocolate consistently outperforms budget alternatives.

Why Composition Matters: Chocolate with proper fat content melts evenly at predictable temperatures and re-solidifies with attractive shine. Additives like stabilizers (common in chocolate chips) prevent smooth melting by interfering with cocoa butter's natural properties.

|

Chocolate Component |

Impact on Melting |

Ideal Range |

|

Cocoa butter |

Creates smooth flow, glossy finish |

32-39% (couverture) |

|

Cocoa solids |

Provides chocolate flavor |

30-70% depending on type |

|

Sugar |

Affects melting temperature |

Varies by chocolate type |

|

Milk solids |

Lowers melting point (milk chocolate) |

12-14% in milk chocolate |

|

Lecithin |

Improves flow, reduces viscosity |

Small amounts acceptable |

|

Stabilizers |

Prevent proper melting |

Avoid for best results |

Quality chocolate designed for professional use contains optimal ratios for reliable melting performance.

Couverture Chocolate: The Professional Choice

When asking what chocolate is best for melting, professionals consistently choose couverture chocolate for superior results.

What Makes It Special: Couverture chocolate contains minimum 32-39% cocoa butter—significantly higher than standard chocolate. This extra cocoa butter creates exceptionally smooth, fluid consistency when melted, perfect for coating and molding applications.

Key Advantages:

- Smooth, glossy finish: Creates professional appearance automatically

- Excellent flow: Coats evenly without thick, clumpy texture

- Proper snap: Sets with satisfying firmness when tempered correctly

- Superior flavor: Real chocolate taste without waxy aftertaste

- Versatile applications: Works for dipping, molding, enrobing, decorating

Tempering Requirement: Couverture requires tempering—heating and cooling to specific temperatures to stabilize cocoa butter crystals. While this adds complexity, the results justify the effort for professional applications.

When to Choose Couverture:

|

Project Type |

Why Couverture Works Best |

|

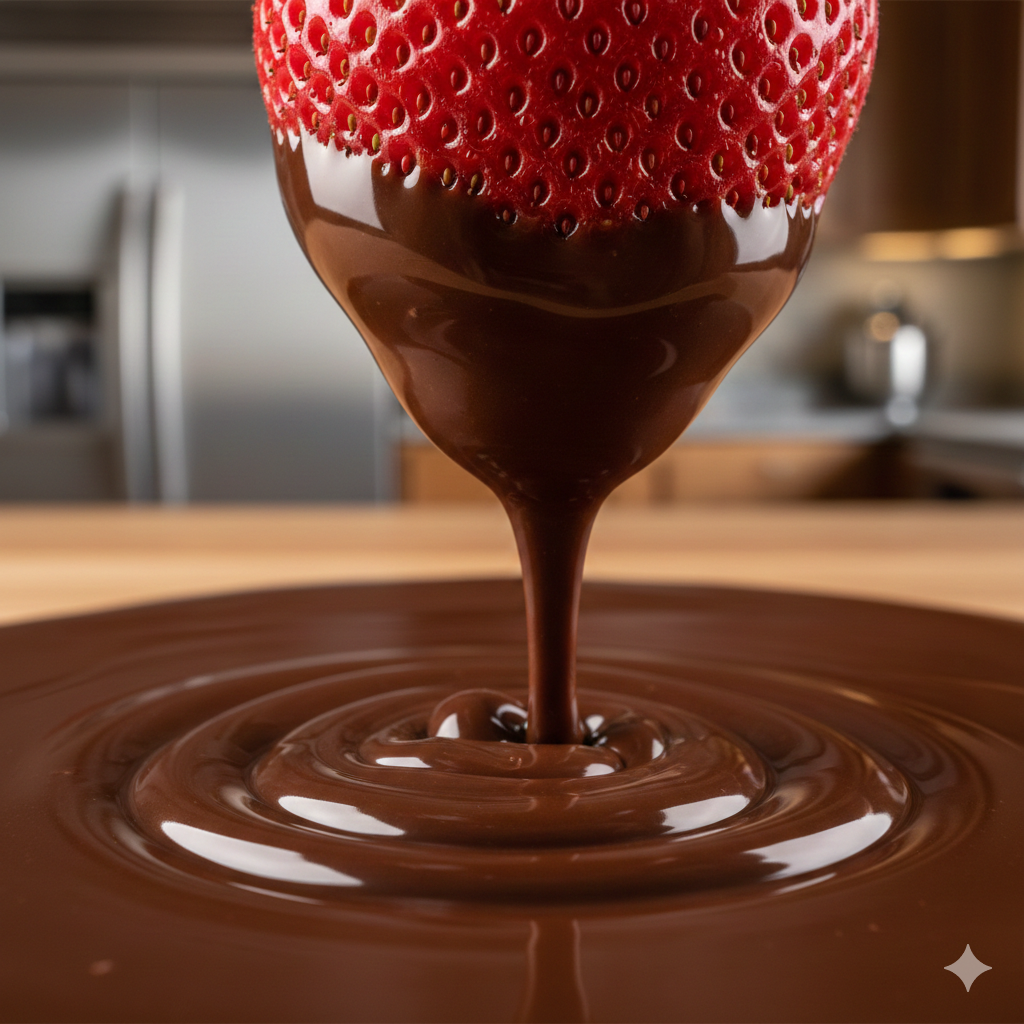

Chocolate-dipped strawberries |

Thin, elegant coating with glossy appearance |

|

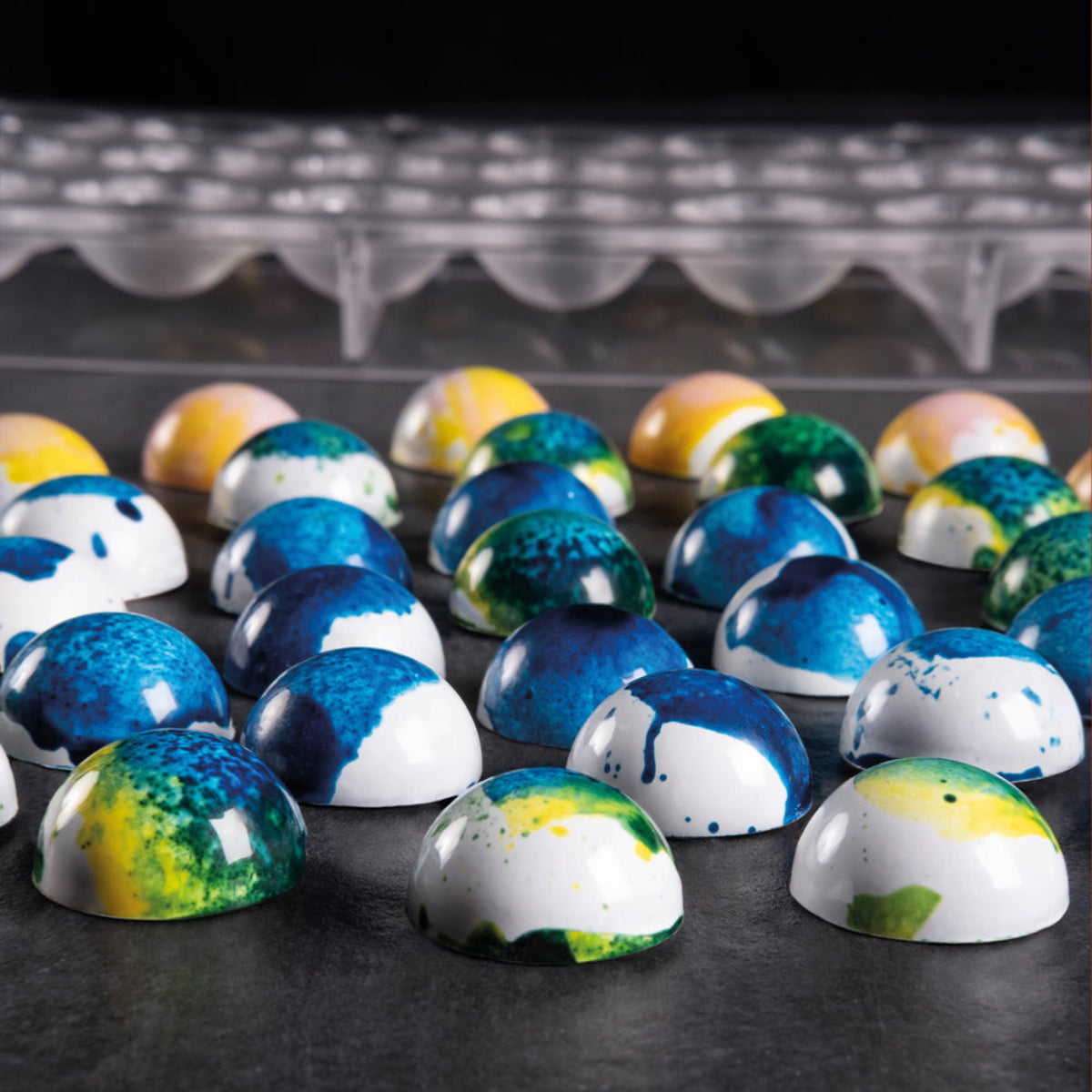

Molded chocolates |

Releases cleanly with professional shine |

|

Chocolate decorations |

Holds intricate details perfectly |

|

Enrobed candies |

Even, thin coating without waste |

|

Competition work |

Professional appearance required |

Investment Worth Making: While more expensive than alternatives, couverture delivers results that distinguish homemade from professional quality. Browse premium options at Zucchero Canada for reliable professional-grade chocolate.

Compound Chocolate: The Easy Alternative

For those seeking convenience when determining what chocolate is best for melting, compound chocolate offers practical advantages.

Composition Difference: Compound chocolate replaces some or all cocoa butter with vegetable fats (palm kernel oil, coconut oil). This substitution eliminates tempering requirements while maintaining workable melting properties.

Major Advantage—No Tempering: Simply melt and use. Compound chocolate sets at room temperature with acceptable shine, making it ideal for beginners or high-volume production where tempering isn't practical.

Trade-offs to Consider:

|

Aspect |

Compound Chocolate |

Couverture Chocolate |

|

Tempering needed |

No—melts and sets easily |

Yes—requires precise technique |

|

Flavor |

Good but slightly waxy |

Superior, pure chocolate taste |

|

Texture |

Softer, melts faster in hand |

Firm snap, heat-resistant |

|

Shine |

Decent but not mirror-like |

Professional glossy finish |

|

Cost |

Budget-friendly |

Premium pricing |

|

Shelf stability |

Excellent, resists bloom |

Good when tempered properly |

Best Uses: Compound chocolate excels at cake pops, casual chocolate-dipping projects, candy making for large batches, practice projects before using expensive couverture, and situations where chocolate will be refrigerated (masks texture differences).

When It's Better: Choose compound for kids' baking projects, high-volume commercial production, or whenever tempering isn't feasible due to time or skill constraints.

Candy Melts: Convenient but Limited

Candy melts represent the most convenient option when considering what chocolate is best for melting, though with notable limitations.

What They Are: Candy melts (also called candy coating or confectionery coating) contain sugar, vegetable fats, milk solids, and flavorings—but typically no real cocoa or cocoa butter. They're designed purely for ease of use.

Convenience Factors:

- Melt in microwave without precision

- No tempering required

- Set quickly at room temperature

- Available in rainbow of colors

- Long shelf life

- Beginner-friendly

Significant Limitations: The best chocolate for melting debate becomes clear when comparing candy melts to real chocolate—the taste simply doesn't compare. Candy melts have sweet, artificial flavor lacking chocolate's complexity and richness. They also create waxy mouthfeel that many find unpleasant.

Appropriate Applications: Cake pops where flavor is secondary to appearance, kids' baking projects prioritizing fun colors, decorative drizzles on cookies or pretzels, quick party treats, and practice projects to learn techniques.

When to Avoid: Skip candy melts for fine chocolates or truffles, elegant desserts where taste matters, professional presentations, gifts for chocolate enthusiasts, or any application where chocolate flavor is the star.

Chocolate Chips vs. Bar Chocolate

Understanding this distinction is crucial when determining what chocolate is best for melting for your specific needs.

Why Chips Resist Melting: Chocolate chips contain stabilizers that help them maintain shape during baking. These same stabilizers interfere with smooth melting, creating thick, clumpy texture rather than fluid consistency needed for coating and dipping.

The Stabilizer Problem: Stabilizers prevent cocoa butter from flowing freely, resulting in chocolate that never achieves the smooth, pourable consistency required for most melting chocolate applications.

|

Feature |

Chocolate Chips |

Bar Chocolate |

|

Stabilizers |

Yes—maintain shape |

No—pure chocolate |

|

Melting consistency |

Thick, clumpy, holds shape |

Smooth, fluid, pourable |

|

Best for |

Baking (cookies, muffins) |

Melting, dipping, coating |

|

Convenience |

Pre-portioned |

Requires chopping |

|

Cost per ounce |

Often more expensive |

Usually better value |

|

Results |

Acceptable for baking only |

Professional for melting |

When Chips Can Work: In emergency situations, chips can be melted with added coconut oil or vegetable shortening (1 tablespoon per cup of chips) to thin consistency. However, results remain inferior to proper melting chocolate.

Bar Chocolate Advantages: Chocolate bars formulated for melting contain no stabilizers, melt smoothly at proper temperatures, and create professional results. The minimal effort of chopping bars pays dividends in final quality.

Chopping Tips: Use a sharp chef's knife on a cutting board. Chop into uniform small pieces (roughly 1/4-inch) for even melting. Uniform size prevents some pieces burning while others remain unmelted.

Dark, Milk, and White Chocolate for Melting

Each chocolate type has unique characteristics affecting melting performance when choosing what chocolate is best for melting.

Dark Chocolate (60-70% Cacao)

Melting Characteristics: Most forgiving and stable chocolate for melting. Higher cocoa content provides structure that tolerates slight temperature variations without seizing or scorching.

Temperature Range: Melts between 115-120°F. Can handle brief overheating better than milk or white chocolate. Sets firmly with excellent snap when properly tempered.

Best For: Chocolate decorations requiring stability, dipping items that need firm coating, molded chocolates, and projects where chocolate will be displayed at room temperature.

Milk Chocolate

Delicate Nature: Contains milk solids that make it more temperature-sensitive than dark chocolate. Requires lower melting temperatures and gentler heating to prevent scorching milk proteins.

Sweet Applications: The familiar sweet, creamy flavor makes milk chocolate ideal for kid-friendly treats, sweeter dipped fruits like bananas, candy coating for broad appeal, and desserts where subtle chocolate flavor is preferred.

Temperature Needs: Melt between 110-115°F—5-10 degrees lower than dark chocolate. Monitor carefully as milk solids burn easily, creating grainy, bitter flavor.

White Chocolate

Most Challenging: Contains no cocoa solids—only cocoa butter, milk solids, and sugar. This composition makes white chocolate the most temperature-sensitive and prone to seizing or scorching.

Special Handling: Never exceed 110°F when melting. Use lowest microwave power (30-40%) and shortest intervals (15-20 seconds). Stir frequently and patiently. Even slight overheating causes irreversible separation.

Unique Benefits: Creates stunning visual contrast against dark desserts, provides neutral base for coloring with colors for chocolate, and offers sweet, creamy flavor without chocolate intensity.

|

Chocolate Type |

Melting Temperature |

Difficulty Level |

Best Applications |

|

Dark (60-70%) |

115-120°F |

Easy—most forgiving |

Decorations, dipping, general use |

|

Milk |

110-115°F |

Moderate—watch carefully |

Sweet treats, kid-friendly projects |

|

White |

105-110°F |

Challenging—very delicate |

Visual contrast, coloring base |

Best Chocolate Brands for Melting

Professional Standards: When determining what chocolate is best for melting, these brands consistently deliver reliable results:

- Callebaut (Belgium): Industry standard for professionals; excellent cocoa butter content

- Valrhona (France): Premium quality; complex flavor profiles; professional favorite

- Guittard (USA): High-quality domestic option; good value for quality ratio

- Cacao Barry (France): Professional-grade; wide variety of cocoa percentages

Accessible Quality Options: For home bakers, these brands offer excellent melting properties at reasonable prices: Ghirardelli baking bars, Baker's chocolate bars, and Lindt excellence bars.

Label Reading Tips: Look for "couverture" designation, cocoa butter as primary fat (not vegetable oils), minimal ingredients list, and cocoa butter content above 32%.

Where to Buy: Specialty baking stores, online chocolate retailers, professional pastry suppliers like Zucchero Canada, and bulk restaurant supply stores.

Key Factors When Choosing Melting Chocolate

Selecting what chocolate is best for melting depends on matching chocolate characteristics to project requirements.

Project Type Matching:

|

Your Project |

Best Chocolate Choice |

Why It Works |

|

Chocolate-dipped strawberries |

Couverture dark or milk |

Thin coating, elegant appearance |

|

Cake pops |

Compound chocolate or candy melts |

No tempering, sets quickly, forgiving |

|

Molded chocolates/bars |

Couverture chocolate |

Professional shine, clean release from molds |

|

Drizzling on baked goods |

Any quality bar chocolate |

Appearance matters less; flavor important |

|

Chocolate decorations |

Couverture dark chocolate |

Holds shape, professional finish |

|

Kids' baking projects |

Candy melts or compound |

Foolproof, colorful, fun |

Additional Considerations:

- Skill level: Beginners succeed with compound chocolate or candy melts before advancing to couverture

- Time available: Tempering adds 30-45 minutes; choose accordingly

- Final appearance needs: Professional presentations require couverture's glossy finish

- Budget: Premium chocolate costs 2-4x more than compound alternatives

- Storage conditions: If serving in warm environments, tempered couverture resists melting better

For specialized applications, consider professional equipment like chocolate melters or Mol d'art chocolate melters that maintain optimal temperatures consistently.

Common Mistakes When Selecting Melting Chocolate

Critical Errors to Avoid:

- Using regular chocolate chips: Stabilizers prevent smooth melting—always choose bars or melting wafers

- Ignoring cocoa butter content: Low cocoa butter (below 30%) creates thick, unworkable consistency

- Buying low-quality chocolate: Compounds labeled "chocolate-flavored coating" contain minimal real chocolate

- Wrong type for project: Using compound chocolate for elegant gifts disappoints with waxy taste

- Not reading ingredients: Vegetable fats besides cocoa butter indicate inferior melting properties

Label Red Flags: "Chocolate-flavored," "artificially flavored," vegetable oils listed before cocoa butter, excessive additives and stabilizers, and suspiciously low prices for "couverture" chocolate.

How to Properly Melt Different Chocolate Types

Understanding melting techniques ensures success with your chosen chocolate for melting.

Temperature Guidelines:

|

Chocolate Type |

Target Melting Temp |

Microwave Power |

Double Boiler |

|

Dark chocolate |

115-120°F |

50% power, 30-sec intervals |

Medium-low heat |

|

Milk chocolate |

110-115°F |

40% power, 20-sec intervals |

Low heat |

|

White chocolate |

105-110°F |

30% power, 15-sec intervals |

Very low heat |

|

Compound/candy melts |

110-115°F |

50% power, 30-sec intervals |

Medium-low heat |

Microwave Method: Place chopped chocolate in microwave-safe bowl. Heat at appropriate power level for specified intervals. Stir thoroughly between each interval—residual heat continues melting. Stop when 80% melted; stir to complete melting.

Double Boiler Method: Simmer 1 inch water in saucepan. Place bowl on top (not touching water). Add chocolate and stir constantly until smooth. Provides gentler, more controlled heating than microwave.

Preventing Disasters: Never let water contact chocolate—even one drop causes seizing. Use completely dry bowls and utensils. Don't cover chocolate while melting—trapped steam causes water droplets. Remove from heat before fully melted to prevent overheating.

Explore professional chocolate melters and Pomati chocolate technology for consistent temperature control in high-volume applications.

Storage Tips for Melting Chocolate

Optimal Conditions: Store chocolate in cool (60-65°F), dry location away from sunlight. Wrap tightly in original packaging or airtight containers. Never refrigerate unless absolutely necessary—temperature fluctuations cause bloom (white streaks).

Shelf Life: Quality chocolate lasts 12-24 months when stored properly. Dark chocolate keeps longest; white chocolate has shortest shelf life due to milk solids. Check "best by" dates when purchasing.

Quality Indicators: Fresh chocolate breaks with clean snap, has glossy surface without streaks, smells pleasant and chocolate-rich, and melts smoothly without graininess. Discard chocolate that smells rancid, has grayish cast throughout, crumbles rather than snaps, or tastes stale.

Conclusion

Determining what chocolate is best for melting depends on your specific project, skill level, and desired results. Couverture chocolate remains the professional standard for superior flavor, glossy appearance, and reliable performance in demanding applications. Compound chocolate offers practical convenience for everyday projects where tempering isn't feasible. Candy melts provide beginner-friendly options for casual, colorful creations. Understanding the characteristics, advantages, and limitations of each chocolate for melting type empowers you to select appropriately for any situation—from elegant chocolate-dipped strawberries to fun kids' treats. Invest in quality chocolate matched to your application for consistently delicious, beautiful results that showcase your effort and skill. Ready to elevate your chocolate work with premium melting chocolate? Explore professional-grade options, specialized chocolate melters, and complete chocolate decorations supplies at Zucchero Canada to support your journey toward chocolate mastery.

References

Beckett, S. T. (2023). The science of chocolate (3rd ed.). Royal Society of Chemistry.

Callebaut. (2023). Chocolate melting and tempering: Professional guide. Barry Callebaut Group.

Figoni, P. (2022). How baking works: Exploring the fundamentals of baking science (4th ed.). Wiley.

Greweling, P. (2023). Chocolates and confections: Formula, theory, and technique for the artisan confectioner (3rd ed.). Wiley.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.