Every chocolatier and confectioner faces the fundamental challenge of transforming solid chocolate into workable liquid form while maintaining proper temperature and texture. A chocolate melting machine solves this challenge efficiently, providing consistent heat distribution and precise temperature control that manual methods simply cannot match. Professional chocolate melters distinguish themselves from makeshift solutions through engineering specifically designed for chocolate's unique properties, delivering gentle, even heating that prevents scorching or seizing while maintaining temperature stability throughout extended working periods.

Professional Chocolate Melters and Tempering Equipment

Compact Chocolate Melters for Artisan Production

Basic chocolate melters provide reliable temperature-controlled melting for general applications. These units feature heated tanks ranging from small capacity models perfect for artisan operations to larger versions serving high-volume producers. The Mol Dart Chocolate Melter 3 kg capacity exemplifies compact professional melting for smaller batches, while the Chocolate Melter 6 kg capacity accommodates more substantial production requirements with consistent temperature control.

Automatic Tempering Systems

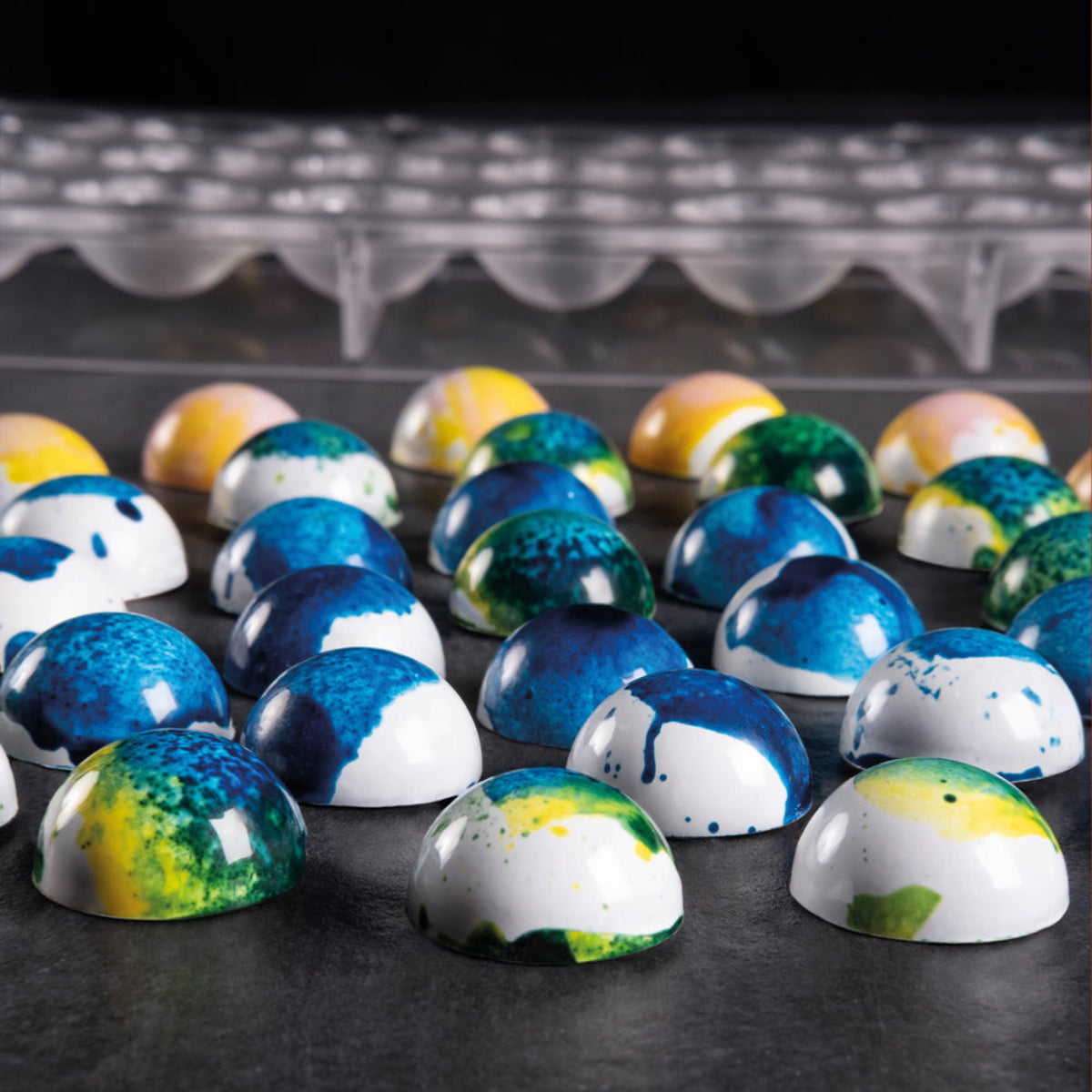

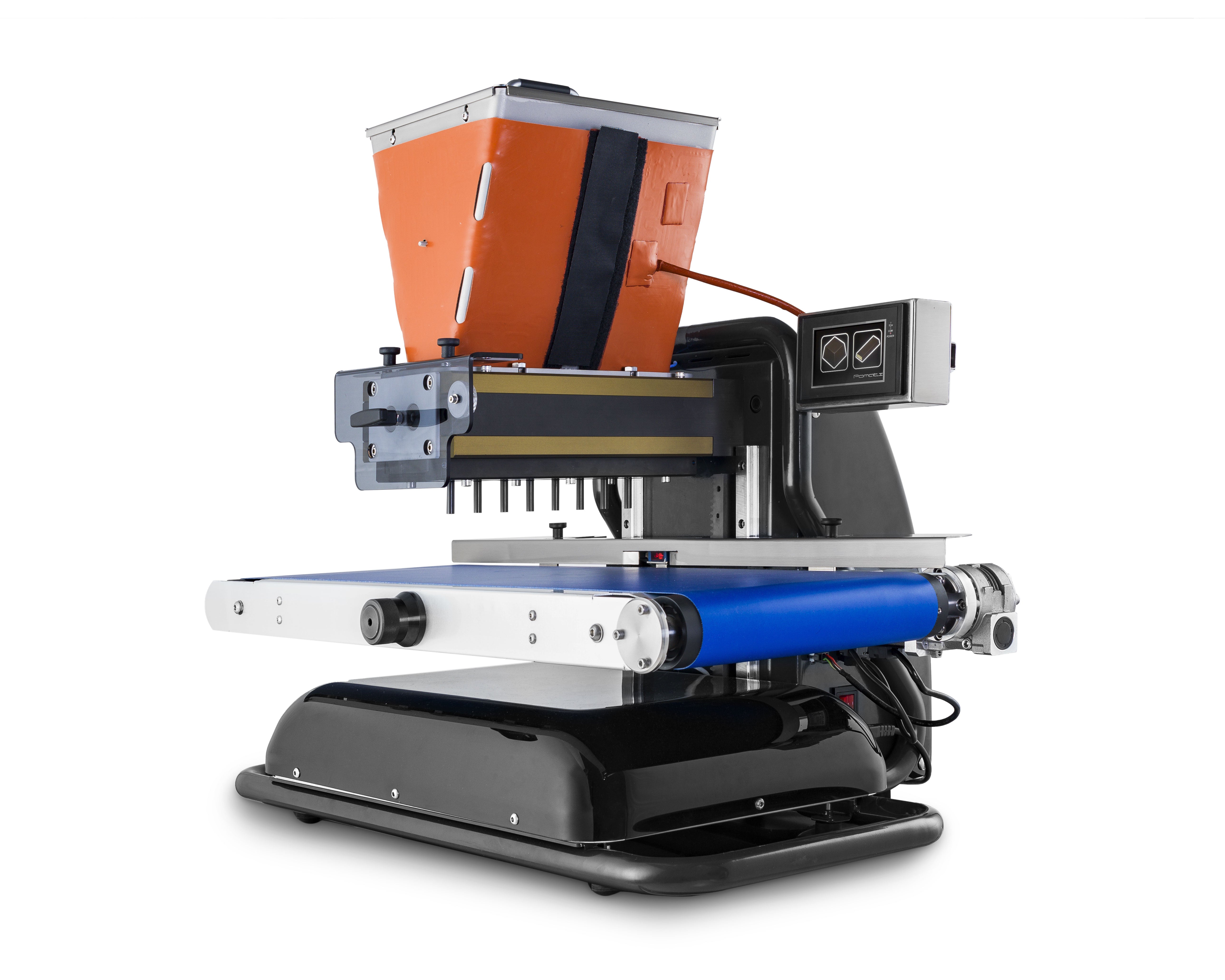

Tempering machines combine melting with the critical crystallization process required for shelf-stable chocolate products. These sophisticated units automatically heat, cool, and reheat chocolate through precise temperature curves that establish proper cocoa butter crystal structure. Without tempering, molded chocolate remains soft, develops bloom, and melts easily at room temperature. Understanding how chocolate tempering machines work reveals why this equipment proves essential for operations producing molded bars, bonbons, or any unrefrigerated chocolate products.

The Automatic Tempering Machine CW 12 kg demonstrates how integrated systems streamline workflow while maintaining professional results across different production requirements. For operations requiring expanded functionality, the FBM Kleego 100 Chocolate Melter Conche combines multiple processes in a single machine.

Chocolate Enrobing Systems

Chocolate enrobing machines represent specialized equipment for coating applications. An enrobing machine creates a continuous chocolate curtain that evenly coats products passing beneath on a conveyor belt. This method delivers consistent coating thickness impossible to achieve through hand-dipping, dramatically increasing production speed while reducing chocolate waste. Our chocolate enrobing machines section features various belt widths and capacities matching different product sizes and production volumes.

Premium Mol Dart Collection

The Mol Dart chocolate melters collection exemplifies equipment designed with chocolate's thermal sensitivity as the primary engineering consideration. These melters use gentle heating systems that protect chocolate from thermal damage through water jackets or ceramic elements that provide indirect warmth rather than direct flame or coil contact.

Equipment Selection Guide for Your Chocolate Business

Calculate Your Production Requirements

Start by calculating your typical batch sizes and daily chocolate consumption. This analysis reveals whether a compact 3 kg melter suffices or if larger capacity equipment prevents constant reloading that interrupts workflow. Remember that melter capacity should accommodate your peak production periods, not just average daily use. Operations primarily dipping truffles or coating nuts need different features than those molding chocolate bars.

Understand Your Tempering Needs

Tempering needs determine whether simple melters suffice or if tempering equipment proves necessary. If you work exclusively with pre-tempered couverture for immediate use, basic melters work perfectly. However, operations molding bars, creating bonbons, or storing products at room temperature require proper tempering for professional results. Learning how to use a chocolate melting machine effectively optimizes your specific applications and ensures consistent product quality.

Assess Available Space and Infrastructure

Measure available counter or floor space carefully, accounting for operational clearances and safe placement away from water sources. Verify electrical requirements as larger melters may need dedicated circuits or specific voltage not standard in all locations. Tabletop models suit compact spaces but limit capacity, while floor-standing equipment demands more room but offers ergonomic advantages and greater volume capacity.

Calculate Long-Term Investment Value

Budget considerations extend beyond purchase price to include operating costs and potential savings. While quality equipment costs more initially, it delivers lower energy consumption, reduced product waste, and minimal maintenance expenses. Calculate total cost of ownership over expected equipment lifespan—often 5-10 years for professional machines—rather than focusing solely on upfront investment.

Transform Your Chocolate Production with Professional Equipment

Achieve Consistent Temperature Control

Temperature consistency represents the most immediate benefit of professional melters, maintaining chocolate within the narrow temperature range required for optimal viscosity and workability. This precision prevents the temperature fluctuations that cause chocolate to thicken prematurely or develop bloom, ensuring every batch performs identically. Precise digital temperature controls maintain chocolate within the specific working range each variety requires—typically 31-32°C for dark, 29-30°C for milk, and 28-29°C for white chocolate.

Increase Production Capacity and Workflow

Production capacity increases dramatically with proper equipment. A chocolate melter holds substantially more product than stovetop methods while maintaining uniform temperature throughout the entire volume. This capacity allows continuous workflow where you can dip, coat, or mold products without stopping to melt additional chocolate. For operations producing enrobed items, this continuity proves essential for maintaining consistent coating thickness and appearance.

Improve Labor Efficiency and Focus

Labor efficiency improves when equipment handles temperature management automatically. Manual melting demands constant attention, pulling staff away from value-adding activities like decorating or packaging. Automated equipment maintains set temperatures without supervision, allowing your team to focus on skilled tasks that directly impact product quality and presentation. This efficiency becomes particularly valuable during high-volume production periods when every minute counts.

Preserve Product Quality Through Gentle Heating

Product quality elevates through gentle, controlled heating that professional melters provide using indirect heating methods. This approach eliminates hot spots that cause localized scorching, ensuring uniform heating throughout the entire chocolate mass while preserving chocolate's delicate flavor compounds and smooth texture. Quality melters use water jackets, heating plates, or ceramic elements that protect chocolate from thermal damage.

Reduce Operating Costs with Energy Efficiency

Energy efficiency in modern equipment reduces operating costs while improving temperature stability. Insulated tanks retain heat effectively, requiring less energy to maintain working temperatures. Digital thermostats cycle heating elements precisely, avoiding the energy waste of continuous heating. These efficiencies compound over time, lowering utility bills while extending equipment lifespan through reduced thermal stress on components.

Ensure Long-Term Reliability and Durability

Durability through quality construction ensures reliable long-term performance. Stainless steel tanks resist corrosion from chocolate acids and repeated cleaning, maintaining sanitary conditions throughout equipment lifespan. Heavy-duty heating elements withstand constant cycling without failure, while robust electronic controls tolerate the demanding conditions of commercial kitchen environments. Easy-clean designs with removable bowls and smooth interior surfaces reduce downtime between batches or when switching chocolate types.

Elevate Your Chocolate Work with Zucchero Canada

Selecting appropriate chocolate melting equipment represents a pivotal decision that influences production efficiency, product quality, and operational profitability. Quality chocolate making equipment enables consistent results that build customer confidence and brand reputation. From simple melters maintaining working temperatures to sophisticated enrobers creating uniform coatings, each equipment category addresses specific production challenges while opening possibilities for expanded product offerings and increased capacity.

At Zucchero Canada, we provide carefully curated chocolate production equipment from manufacturers who understand confectionery demands. Our chocolate machines selection spans entry-level equipment for emerging chocolatiers to production-scale machinery for established operations, ensuring we can support businesses at every growth stage with expert guidance and reliable equipment.

We invite you to explore our comprehensive chocolate melters collection and discover how professional equipment can transform your production capabilities. Our experienced team offers personalized guidance on equipment selection, helping match specific features and capacities to your operational requirements and budget parameters. For detailed product specifications, capacity recommendations, or assistance planning your chocolate production workflow, contact our knowledgeable staff who understand both the technical aspects and practical realities of professional chocolate work.

Visit zuccherocanada.ca to browse our complete chocolate equipment catalog, or reach out directly for expert consultation on your specific needs. We're dedicated to supporting your chocolate-making success with quality machinery, technical expertise, and ongoing customer service as your business grows and evolves.