Can you add food colouring to candy melts? This common question arises whenever candy makers want custom colors beyond standard pre-colored options. The answer is yes—but only with the right type of food colouring to candy melts. Using the wrong coloring causes candy melts to seize into an unusable, grainy mess. This guide explains which colors work, which fail catastrophically, and professional techniques for achieving vibrant custom colors safely and reliably.

Understanding Candy Melts Composition

Candy melts differ significantly from real chocolate, and this composition determines which food colouring to candy melts works successfully.

What Candy Melts Contain: Sugar, vegetable oils (palm kernel, coconut), milk solids, flavorings, and lecithin. Notably absent: cocoa butter, which real chocolate contains. This fat-based composition is critical to understanding coloring options.

Oil-Based Foundation: Candy melts are essentially fat and sugar held in suspension. Water disrupts this delicate balance catastrophically, causing immediate seizing—when smooth melted candy transforms into thick, grainy, unusable sludge.

|

Component |

Purpose |

Coloring Impact |

|

Vegetable oils |

Provides melting/flowing properties |

Requires oil-soluble colors |

|

Sugar |

Sweetness, structure |

Doesn't affect color choice |

|

Milk solids |

Flavor, texture |

No impact on coloring |

|

Lecithin |

Emulsifier, smooth texture |

Helps distribute oil-based colors |

Understanding this oil-based composition is fundamental to answering can you add food colouring to candy melts correctly.

The Short Answer: Yes, But Not All Food Coloring Works

Can you add food colouring to candy melts? Yes—but exclusively oil-based or fat-soluble types. Water-based colors cause instant failure.

Critical Rule: Never use standard liquid food coloring (the drops you buy at grocery stores) in candy melts. These water-based colors cause immediate seizing, ruining your entire batch beyond recovery.

What Works:

- Oil-based liquid food coloring

- Fat-soluble powder colors

- Cocoa butter-based colors

What Fails:

- Standard liquid food coloring (water-based)

- Most gel colors (contain water)

- Natural juice or extract colors (water-based)

Setting proper expectations prevents costly mistakes when learning to add food colouring to candy melts.

Why Water-Based Food Coloring Fails

Understanding the chemistry explains why the wrong answer to can you add food colouring to candy melts creates disaster.

The Seizing Problem: When water contacts melted candy (or chocolate), it causes fat particles to clump together instantly. The smooth, flowing candy transforms into thick, grainy paste within seconds—completely unusable for dipping, molding, or coating.

Chemistry Explanation: Water and oil don't mix. When water droplets contact oil-based candy melts, they create localized crystallization that spreads rapidly throughout the entire batch. The sugar dissolves in the water, separating from the fats, and the mixture seizes.

Visual Result: Smooth, glossy melted candy suddenly becomes thick, matte, grainy paste resembling wet sand. No amount of heating or stirring fixes seized candy—it's permanently ruined.

|

Water Source |

What Happens |

Recovery Possible? |

|

Liquid food coloring |

Immediate seizing |

No—discard batch |

|

Gel with water content |

Gradual thickening, then seizing |

No—discard batch |

|

Steam from double boiler |

Moisture causes seizing |

No—prevention only |

|

Wet utensils |

Partial seizing, clumping |

No—start fresh |

Common Water-Based Colors to Avoid: Grocery store liquid drops (McCormick, etc.), most gel food colors, natural extracts, and juice-based colors.

Oil-Based Food Coloring: The Right Choice

Oil-based colors provide the correct answer when asking can you add food colouring to candy melts safely.

Why They Work: Oil-based food coloring mixes seamlessly with candy melts' vegetable oil composition. No water means no seizing—colors blend smoothly, creating vibrant, stable results.

Mixing Characteristics: Oil-based colors incorporate easily into melted candy with simple stirring. They don't affect texture, setting time, or final consistency. Colors remain stable during melting and setting cycles.

Color Intensity: Oil-based colors are highly concentrated, requiring only 2-3 drops per cup of candy melts for vivid colors. Start with minimal amounts—adding more is easy, but you cannot remove excess color.

Professional Pavoni Italia Oil-Based Colors

For serious candy makers seeking superior results, Pavoni Italia offers professional oil-based colors for chocolate that work flawlessly with candy melts. These Italian-crafted colors provide exceptional intensity, requiring minimal product for vibrant results while maintaining perfect candy melt consistency.

Pavoni's oil-soluble color range includes every shade imaginable, from pastel tints to bold primaries. Their professional formulation ensures colors won't separate, fade, or affect candy melts' texture—critical for commercial applications or important projects. The concentrated formula makes them economical despite premium pricing.

Where to Buy: Quality oil-based colors are available at specialty baking stores, online retailers (TruColor, Chefmaster Oil Candy Colors), and professional suppliers. For guaranteed professional results, explore the complete Pavoni Italia range at Zucchero Canada—Canada's exclusive source for these premium Italian colors.

Gel Food Coloring: Proceed with Caution

Gel colors present a controversial answer to can you add food colouring to candy melts that requires careful consideration.

The Problem: Most gel food colors contain water or glycerin, which can cause seizing. However, some specialty "candy melts safe" gels exist with oil-based formulas that work.

When Gels Might Work: Only gels specifically labeled "oil-based" or "candy melts safe" should be attempted. Even then, test with small batches before committing to full projects.

Testing Method: Add tiny amount (toothpick tip) of gel to 1 tablespoon melted candy. Stir thoroughly for 30 seconds. If candy remains smooth and glossy, the gel is safe. If it thickens, becomes grainy, or loses shine, the gel contains water—avoid it.

Better Alternatives: Oil-based liquid colors or powder colors offer more reliable results without the guesswork and risk associated with gel colors.

Powder Food Coloring Options

Fat-soluble powder colors provide another excellent answer to can you add food colouring to candy melts with unique advantages.

How Powders Work: Fat-soluble powder colors dissolve directly into candy melts' oils, creating smooth, even color distribution. Unlike water-based powders (like drink mixes), fat-soluble versions are specifically formulated for chocolate and candy work.

Mixing Technique: Add small amount of powder to melted candy and stir vigorously for 1-2 minutes. Powders take slightly longer to incorporate than liquids but distribute beautifully once dissolved. Use a small spatula or whisk for thorough mixing.

Advantages:

- Longest shelf life of any coloring type

- No risk of seizing (when using fat-soluble versions)

- Excellent for achieving very vibrant, saturated colors

- Professional choice for commercial candy making

Pavoni Italia Professional Powdered Colors

Pavoni Italia's powdered colors represent the pinnacle of professional candy and chocolate coloring. Their fat-soluble powder range includes standard colors, metallized finishes, and pearl effects that elevate candy melts from simple treats to artistic creations.

These professional powders offer unmatched color intensity—a tiny amount creates vivid results. The fine particle size ensures smooth incorporation without grittiness. For professional candy makers, chocolatiers, or serious hobbyists, Pavoni powders deliver consistent, competition-quality results every time.

Available exclusively through Zucchero Canada, Pavoni Italia powdered colors bring European professional standards to Canadian candy makers.

Candy Melt Color Discs vs. Adding Color

When considering can you add food colouring to candy melts, the alternative option is buying pre-colored discs.

Pre-Colored Discs: Manufacturers like Wilton and Merckens offer candy melts in numerous colors. These provide foolproof color without any coloring steps.

|

Aspect |

Pre-Colored Discs |

Adding Your Own Color |

|

Convenience |

Melt and use immediately |

Requires extra step |

|

Color range |

Limited to manufacturer options |

Unlimited custom colors |

|

Cost |

More expensive per pound |

More economical |

|

Consistency |

Guaranteed identical color |

Requires careful measuring |

|

Storage |

Need multiple bags of colors |

One white base + colors |

|

Customization |

Limited mixing options |

Complete creative control |

Best Approach: Keep white candy melts as your base and quality oil-based colors on hand. This provides flexibility while maintaining the option to use convenient pre-colored discs when they match your needs perfectly.

Step-by-Step: How to Add Food Coloring to Candy Melts

Process Overview:

|

Step |

Action |

Details |

|

1. Melt candy |

Microwave at 50% power, 30-sec intervals |

Stir between intervals until smooth |

|

2. Cool slightly |

Let candy cool 1-2 minutes |

Prevents color degradation from heat |

|

3. Add color |

Start with 2-3 drops oil-based color |

Or tiny amount of powder |

|

4. Stir thoroughly |

Mix 30-60 seconds until uniform |

No streaks should remain |

|

5. Test shade |

Dip spoon and let set on parchment |

Dried color shows true shade |

|

6. Adjust |

Add more color if needed |

Add drops gradually |

Timing Matters: Add color after candy melts completely and cools slightly. Excessive heat can degrade some colors, affecting vibrancy.

How Much Color: Start conservatively with 2-3 drops per cup of candy melts. You can always add more, but cannot remove excess. Test on small portion first before coloring entire batch.

Achieving Desired Shades: For pastel tints, use 1-2 drops maximum. For vivid colors, add 4-6 drops. For deep, saturated shades, use 8-10 drops or more. Record successful ratios for future consistency.

Troubleshooting: If candy thickens after adding color, you likely used water-based coloring—discard and start fresh. If color looks streaky, stir longer and more vigorously.

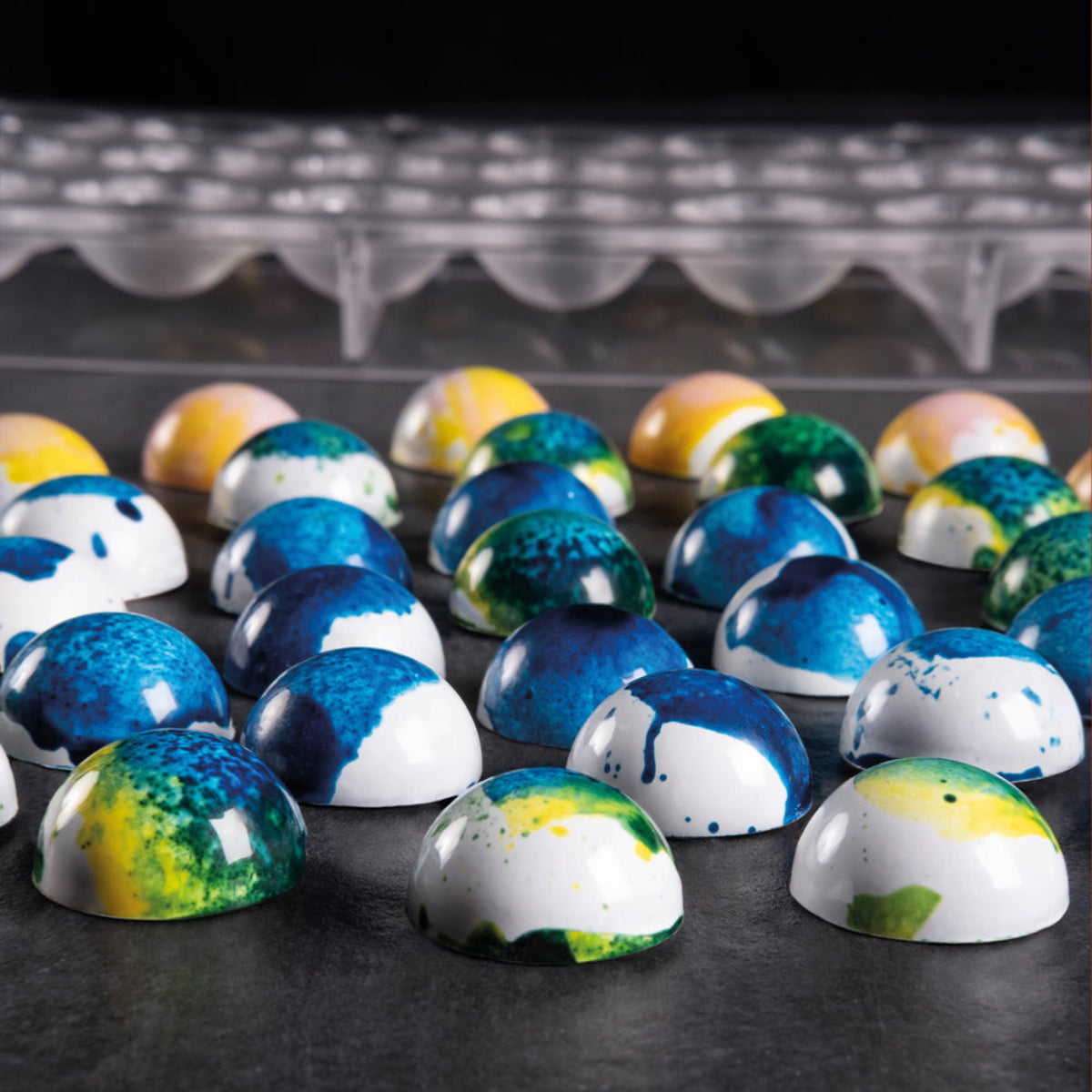

Professional Coloring with Spray Guns

An innovative answer to can you add food colouring to candy melts involves surface coloring rather than mixing color throughout.

Alternative Approach: Instead of coloring candy melts before molding, use white/light-colored candy melts and apply color to the surface after setting. This technique creates stunning effects impossible with mixed-in color.

KREA Swiss Spray Gun Technology

Professional candy makers and chocolatiers now embrace airbrush technology for superior coloring candy melts results. Zucchero Canada exclusively represents KREA Swiss spray guns in Canada—Swiss-engineered precision tools that revolutionize candy and chocolate decoration.

Why Spray Coloring Excels:

- Gradient effects: Create smooth color transitions from light to dark

- Metallic finishes: Apply gold, silver, copper, or pearl effects

- Velvet texture: Achieve that coveted velvety appearance

- Time efficiency: Color dozens of pieces in minutes

- No seizing risk: Color stays on surface, never contacts molten candy

KREA Swiss spray guns handle both water-based and oil-based food color sprays with equal precision. Their advanced atomization creates ultra-fine mist for professional, even coverage. The Swiss engineering ensures consistent pressure and flow—critical for uniform results.

Perfect For: Wedding favors requiring elegant finishes, holiday treats with metallic accents, commercial production demanding efficiency, competition pieces needing flawless appearance, and any project where visual impact matters most.

Professional Combination: Pair Pavoni Italia colors for chocolate with KREA Swiss airbrush spray guns for the ultimate professional candy coloring system. This Italian-Swiss partnership delivers results unattainable through traditional hand-coloring methods.

Discover KREA Swiss spray guns exclusively at Zucchero Canada—transforming how Canadian professionals approach candy and chocolate decoration.

Common Mistakes to Avoid

|

Mistake |

Consequence |

Solution |

|

Using water-based coloring |

Immediate seizing, ruined batch |

Only use oil-based or fat-soluble colors |

|

Adding too much color at once |

Cannot lighten if too dark |

Start with 2-3 drops, add gradually |

|

Not testing first |

Waste entire batch if wrong type |

Test with 1 tablespoon candy first |

|

Overheating candy melts |

Scorched, thick, unusable |

Melt at 50% power with frequent stirring |

|

Poor mixing |

Streaky, uneven color |

Stir vigorously for 30-60 seconds |

|

Using wet utensils |

Seizing from moisture |

Ensure all tools completely dry |

Prevention: These mistakes ruin batches permanently. Taking time to use correct colors and proper technique saves money and frustration.

Best Practices for Colored Candy Melts

Quality Ingredients: Start with quality candy melts (Merckens, Ghirardelli, or professional brands) and premium food coloring like Pavoni Italia. Quality ingredients produce superior results worth the modest additional cost.

Temperature Control: Melt candy at 50% microwave power or low double boiler heat. Overheating causes thick, unworkable consistency and can degrade colors.

Working in Batches: Color small amounts first to test shades before committing full quantities. This prevents waste if color doesn't match expectations.

Storage: Store colored candy in airtight containers at room temperature (60-70°F). Properly stored, colored candy melts last 6-12 months without fading.

Consistency Tips: Measure candy melts by weight (not volume) and record exact drops of color used. This creates reproducible results for future projects requiring identical colors.

Creative Color Ideas and Techniques

Custom Color Mixing: Combine primary colors to create custom shades. Red + yellow = orange. Blue + yellow = green. Red + blue = purple. Add white candy melts to any color for pastel tints.

Ombre Effects: Pour three shades of same color (light, medium, dark) in layers for graduated color transitions. Beautiful for cake pops and molded candies.

Marbling: Drizzle contrasting color into melted candy and swirl gently with toothpick before molding. Creates unique patterns in each piece.

Metallic Finishes: Use Pavoni Italia metallized powdered colors for gold, silver, bronze, or copper effects. Perfect for luxury gifts and celebrations.

Seasonal Palettes: Pastels for spring/Easter, vibrant primary colors for summer, warm oranges and browns for fall, deep reds and greens for winter holidays.

Conclusion

Can you add food colouring to candy melts? Absolutely—when using oil-based liquid colors or fat-soluble powder colors specifically formulated for chocolate and candy work. Water-based colors cause instant, irreversible seizing that ruins batches completely. Understanding this fundamental chemistry principle ensures success every time. For professional results, Pavoni Italia professional colors provide unmatched intensity and reliability, while KREA Swiss spray guns offer innovative surface coloring alternatives that create effects impossible through traditional methods. Both professional solutions are exclusively available in Canada through Zucchero Canada, bringing European quality and Swiss precision to Canadian candy makers and chocolatiers. Ready to create custom-colored candy melts with professional results? Explore premium food coloring, colors for chocolate, powdered colors, and revolutionary airbrush spray guns at Zucchero Canada—your exclusive Canadian source for professional candy and chocolate decoration supplies.

References

Beckett, S. T. (2023). The science of chocolate (3rd ed.). Royal Society of Chemistry.

Figoni, P. (2022). How baking works: Exploring the fundamentals of baking science (4th ed.). Wiley.

Greweling, P. (2023). Chocolates and confections: Formula, theory, and technique for the artisan confectioner (3rd ed.). Wiley.

Hartel, R. W., & von Elbe, J. H. (2023). Food color chemistry and applications. Springer International Publishing.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.