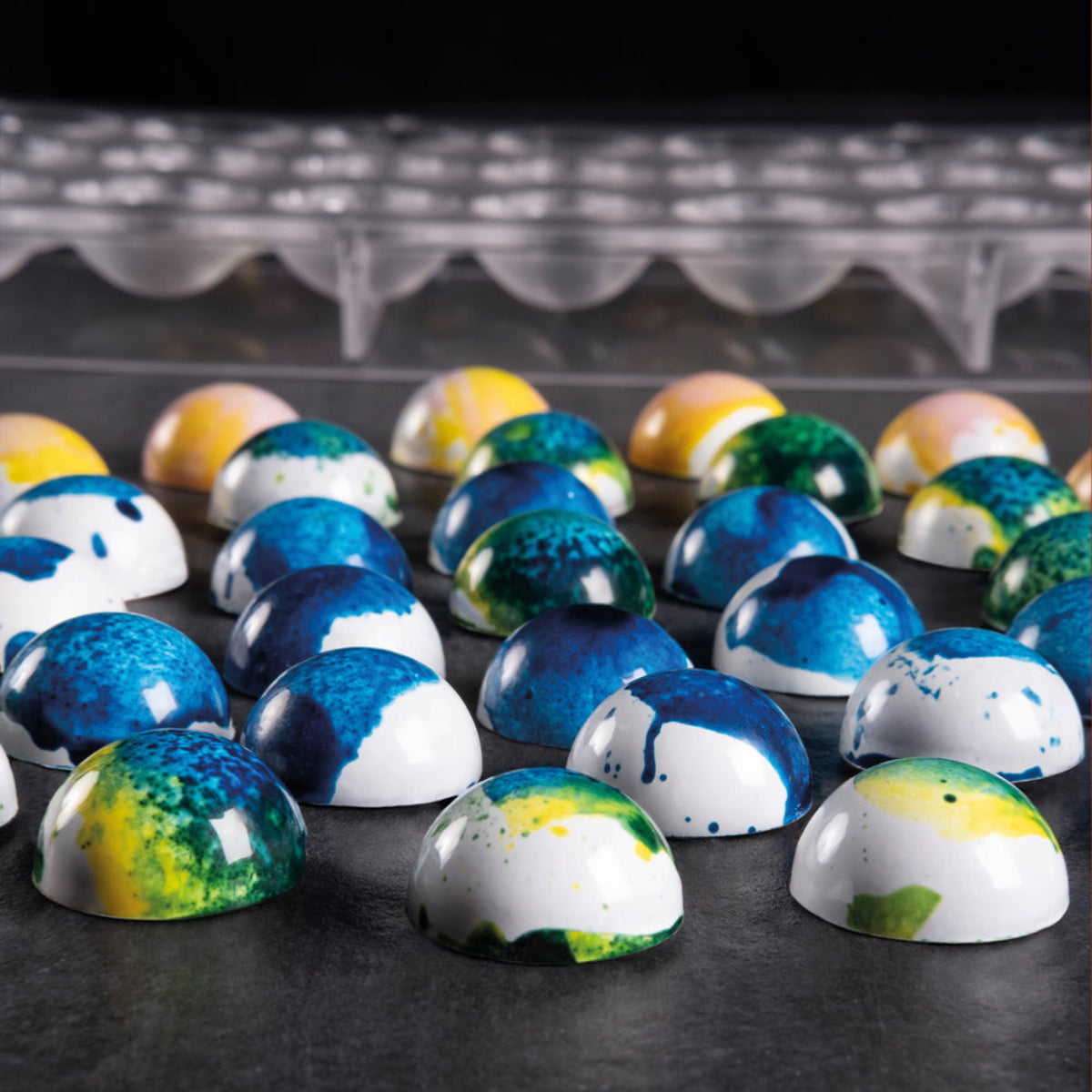

Chocolate molds represent a significant investment for any chocolatier, whether you're a professional artisan or an enthusiastic home baker. These precision tools not only influence the appearance of your final creations but also affect the chocolate's surface quality, release properties, and overall professional finish. Proper storage of chocolate molds is often overlooked, yet it directly impacts their longevity, functionality, and the quality of chocolates they produce.

This comprehensive guide explores the science behind chocolate mold storage, material-specific requirements, environmental considerations, and professional systems for organizing your collection. By implementing these expert storage techniques, you'll protect your investment, maintain optimal mold performance, and ensure consistent, high-quality chocolate production for years to come.

Understanding Your Chocolate Molds' Storage Needs

Different mold materials have unique storage requirements based on their physical properties and vulnerability to specific environmental factors.

Polycarbonate Mold Storage Fundamentals

Polycarbonate molds—the gold standard for professional chocolate making—require specific storage conditions to maintain their clarity, shine, and release properties:

Material Characteristics That Affect Storage:

-

Rigid but somewhat flexible structure that can warp under pressure or heat

-

Scratch-susceptible surface that needs protection from abrasion

-

Potential to absorb odors from surrounding environments

-

Sensitivity to prolonged UV exposure which can cause yellowing

Primary Storage Concerns:

-

Preventing surface scratches that transfer to chocolate

-

Avoiding warping from improper stacking or weight distribution

-

Protecting from dust accumulation that can affect chocolate finish

-

Shielding from strong odors that can be absorbed and transferred to chocolate

Silicone Mold Storage Requirements

Silicone molds, popular for their flexibility and easy release properties, have different storage needs:

Material Characteristics That Affect Storage:

-

Highly flexible material that can become permanently deformed

-

Porous surface that can trap moisture and harbor mold growth

-

Strong tendency to attract dust due to static properties

-

Susceptibility to absorbing and retaining strong odors

Primary Storage Concerns:

-

Preventing deformation from improper folding or compression

-

Keeping completely dry to prevent mold or mildew development

-

Protecting from dust accumulation

-

Isolating from strong-smelling ingredients and chemicals

PET Plastic Mold Storage Considerations

Less expensive PET plastic molds require specific storage approaches:

Material Characteristics That Affect Storage:

-

Lower heat resistance than polycarbonate

-

More prone to scratching and clouding

-

Less dimensional stability, making them more susceptible to warping

-

Generally shorter lifespan requiring more protective storage

Primary Storage Concerns:

-

Avoiding heat exposure that can cause warping or melting

-

Preventing stacking that can create pressure points and deformation

-

Protecting surfaces from scratching

-

Extending usable life through proper handling

Metal Mold Storage Guidelines

Traditional metal molds (typically tin, aluminum, or stainless steel) have unique storage requirements:

Material Characteristics That Affect Storage:

-

Susceptibility to oxidation or corrosion (especially tin molds)

-

Potential for denting or bending under pressure

-

Excellent heat conductivity that affects handling

-

Durability that can last generations with proper care

Primary Storage Concerns:

-

Preventing oxidation and corrosion from moisture exposure

-

Protecting from impact damage that can dent or warp the mold

-

Avoiding metal-to-metal contact that can cause abrasion

-

Maintaining pristine surfaces for proper chocolate release

Creating Optimal Environmental Conditions

The environment in which you store chocolate molds significantly impacts their longevity and performance. Creating and maintaining ideal conditions requires attention to several key factors.

Temperature Control for Mold Storage

Temperature fluctuations can cause material expansion and contraction that damages molds over time:

Ideal Temperature Range:

-

Store molds at consistent room temperature between 65-75°F (18-24°C)

-

Avoid storage near heat sources such as ovens, dishwashers, or heating vents

-

Keep away from direct sunlight which can heat molds unevenly

-

Never store in attics, garages, or outbuildings with extreme temperature variations

Temperature Monitoring:

-

Consider using a simple thermometer in your storage area

-

Be especially vigilant during seasonal changes when indoor temperatures may fluctuate

-

If professional storage is available, climate-controlled environments provide optimal conditions

Humidity Considerations for Long-Term Storage

Moisture is particularly problematic for chocolate molds and can lead to numerous issues:

Ideal Humidity Range:

-

Maintain relative humidity between 30-50%

-

Too dry (<30% RH): Can cause some plastics to become brittle over time

-

Too humid (>50% RH): Creates conditions for mold growth, oxidation of metal molds, and general degradation

Humidity Management:

-

Use silica gel packets in sealed storage containers to absorb excess moisture

-

Consider a small dehumidifier in storage areas with persistent dampness

-

Ensure molds are completely dry before storing them

-

In extremely humid climates, consider climate-controlled storage solutions

Light Exposure Management

Light, particularly UV light, can degrade plastic molds over time:

Light Protection Strategies:

-

Store molds in opaque containers that block light completely

-

Keep storage areas away from windows or direct sunlight

-

If using clear storage containers, select those with UV protection properties

-

Be particularly careful with clear polycarbonate molds, which are more susceptible to UV degradation

Odor Control in Storage Areas

Chocolate molds can absorb ambient odors that transfer to finished chocolates:

Odor Management Approaches:

-

Store molds away from strong-smelling foods and ingredients

-

Keep separate from cleaning supplies, paints, or chemicals

-

Avoid storage in kitchens where cooking odors are prevalent

-

Consider dedicated storage spaces away from food preparation areas

-

For small collections, store with activated charcoal odor absorbers

Physical Storage Systems and Organization

Beyond environmental conditions, the physical organization and protection of molds is crucial for maintaining their quality.

Vertical vs. Horizontal Storage Systems

The orientation of mold storage impacts space utilization and mold protection:

Vertical Storage Benefits:

-

Reduces pressure points that can cause warping

-

Allows quick visual identification of molds

-

Often requires less total space

-

Prevents molds from nesting together which can cause sticking

Implementation Options:

-

Modified file organizers with dividers

-

Custom-built vertical slots in drawers or cabinets

-

Commercial chocolate mold racks (available from specialty suppliers)

-

DIY systems using corrugated plastic sheet dividers

Horizontal Storage Considerations:

-

Works well for flexible silicone molds

-

Requires proper separation between stacked molds

-

Needs sufficient supporting surface to prevent warping

-

More space-efficient for larger collections

Implementation Options:

-

Flat drawers with non-stick liners

-

Shallow storage containers with dividers

-

Slide-out trays in dedicated cabinets

-

Drawer systems with custom inserts

Material Separation and Protection

Proper separation prevents damage from mold-to-mold contact:

Effective Separation Materials:

-

Acid-free tissue paper (preferred for polycarbonate molds)

-

Microfiber cloths (excellent for preserving polished surfaces)

-

Food-grade parchment paper (good temporary option)

-

Non-textured, non-shedding materials (to prevent pattern transfer)

Separation Techniques:

-

Wrap individual molds completely rather than just placing material between them

-

For polycarbonate molds, wrap mold cavities facing inward with protective material

-

Use consistent wrapping methods for easy identification

-

Consider color-coding separation materials for seasonal or type-based organization

Container Selection for Different Mold Types

The right containers help maintain environmental control and physical protection:

For Polycarbonate Molds:

-

Rigid containers that prevent compression

-

Ideally with customizable dividers

-

Solid colors to block light

-

Latching lids for dust protection

For Silicone Molds:

-

Flat, rigid containers preventing folding

-

Shallow designs allowing single-layer storage

-

Good air circulation to prevent moisture accumulation

-

Food-grade containers if space is shared with ingredients

For Metal Molds:

-

Containers with low humidity and good air flow

-

Non-reactive materials that won't promote oxidation

-

Sturdy design to prevent impact damage

-

Consider wooden boxes lined with acid-free paper for vintage molds

Organizational Systems for Mold Collections

Efficient organization systems save time and prevent unnecessary handling:

Categorization Approaches:

-

By shape/type (tablets, bonbons, figures, etc.)

-

By season or holiday usage

-

By manufacturer if maintenance requirements differ

-

By frequency of use (daily, weekly, seasonal)

Labeling Systems:

-

Photograph molds before storage and attach image to container

-

Use clear, consistent labeling with mold number/name

-

Consider QR codes linking to digital catalog for extensive collections

-

Include purchase date information for warranty and replacement planning

Professional Storage Techniques

Professional chocolatiers implement advanced storage methods to protect their significant mold investments.

Clean-Before-Storage Protocols

Proper cleaning prior to storage prevents numerous problems:

Essential Pre-Storage Cleaning:

-

Remove all chocolate residue, particularly from detailed areas

-

Ensure molds are completely dry before storage

-

Avoid using detergents that can leave residue

-

For polycarbonate molds, polish with microfiber cloth before storage

-

For metal molds, ensure complete dryness and consider light oiling for long-term storage

Inspection Process:

-

Check for hairline cracks or damage before storage

-

Verify all cavities are completely clean

-

Ensure no moisture remains trapped in crevices

-

For magnetic molds, verify all components are clean and functioning

Rotation Systems for Mold Preservation

Strategic mold rotation extends the life of your entire collection:

Rotation Benefits:

-

Prevents excessive wear on favorite molds

-

Ensures even aging across your collection

-

Allows regular inspection of less-used molds

-

Creates natural inventory opportunities

Implementation Approaches:

-

Document usage frequency for high-use molds

-

Create seasonal rotation schedules tied to production calendars

-

For professional settings, implement formal rotation tracking

-

Consider having duplicate molds for your most popular designs

Seasonal Storage Transitions

Many chocolate operations have seasonal production shifts requiring storage changes:

Seasonal Transition Process:

-

Deep clean molds at season's end before storage

-

Document any molds needing replacement before next season

-

Use enhanced protection for long-term seasonal storage

-

Create seasonal "kits" with all needed molds grouped together

-

Schedule mid-storage inspections for seasonal molds

Long-Term Storage Enhancements:

-

Additional desiccant packets for seasonal molds

-

More robust wrapping for extended storage periods

-

Climate-controlled options for valuable seasonal collections

-

Documentation of storage location if different from regular-use molds

Storage During Transportation

Proper transport methods prevent damage when moving molds:

Professional Transport Approaches:

-

Custom-cut foam inserts for valuable molds

-

Individual wrapping plus outer container protection

-

Rigid containers that prevent compression during transit

-

Temperature-controlled shipping methods for valuable collections

-

Vibration-dampening materials for delicate or vintage molds

Common Storage Mistakes and Solutions

Understanding frequent storage errors helps prevent damage to your mold collection.

Stack Weight Distribution Errors

Improper stacking creates pressure points that damage molds:

Common Mistake: Stacking heavy molds on top of lighter, more delicate ones, causing warping or distortion.

Solution: Store molds by weight, with heaviest items at the bottom of stacks or in lower drawers. Better yet, implement vertical storage systems to eliminate stacking entirely.

Improper Nesting Habits

Nesting molds together saves space but causes multiple problems:

Common Mistake: Storing molds nested inside one another, which can cause suction, sticking, and difficulty separating them later.

Solution: Never nest molds directly together. If space constraints require nesting, use ample separation material between each mold and limit nesting to just 2-3 molds of the same design.

Inadequate Cleaning Before Storage

Residue left on molds leads to contamination and damage:

Common Mistake: Storing molds with microscopic chocolate residue that hardens during storage and becomes difficult to remove later.

Solution: Implement a thorough cleaning protocol using appropriate methods for each mold type, with special attention to detailed areas and crevices.

Cross-Contamination of Odors

Odor transfer ruins the flavor of future chocolates:

Common Mistake: Storing chocolate molds near strong-smelling items or ingredients, resulting in odor absorption that affects chocolate flavor.

Solution: Maintain dedicated storage areas away from spices, essential oils, cleaning products, and strong-smelling foods. Consider sealed containers with activated charcoal odor absorbers.

Storage Solutions for Different Space Constraints

Effective storage systems can be implemented regardless of available space.

Small Space Solutions for Home Chocolatiers

Limited space requires creative storage approaches:

Under-Bed Storage Systems:

-

Shallow, wheeled containers with dividers

-

Custom-built trays that slide under beds

-

Humidity indicators and desiccant packets to monitor conditions

-

Dust covers for additional protection

Vertical Wall Systems:

-

Modified file or magazine racks mounted to walls

-

Custom pegboard systems with specialized holders

-

Over-door organizers adapted for mold storage

-

Slotted shelving systems that maximize vertical space

Multi-Use Furniture Options:

-

Storage ottomans with custom inserts

-

Coffee tables with storage compartments

-

Dedicated cabinet space with custom dividers

-

Repurposed CD/DVD storage furniture

Mid-Scale Business Storage Solutions

Growing chocolate businesses need scalable storage systems:

Modular Commercial Systems:

-

Industrial drawer systems with custom foam inserts

-

High-density sliding storage racks

-

Clear-front cabinets for visual inventory management

-

Barcode or QR code tracking systems for quick location

Converted Office Furniture:

-

Flat file cabinets traditionally used for architectural drawings

-

Lateral file cabinets with custom dividers

-

Map drawers repurposed for horizontal mold storage

-

Library card catalog units for smaller molds

Kitchen Equipment Adaptations:

-

Bakery rack systems with sheet pan slide-ins

-

Modified speed rack covers to create dust-proof storage

-

Bun pan racks with custom dividers

-

Commercial kitchen storage with dedicated mold sections

Professional Large-Scale Production Storage

Large chocolate operations require comprehensive storage solutions:

Dedicated Storage Rooms:

-

Climate-controlled environments with monitoring systems

-

Custom-built shelving designed specifically for mold collections

-

Inventory management systems with tracking software

-

Security protocols for valuable mold collections

Automated Retrieval Systems:

-

Vertical carousels for high-density storage

-

Barcode scanning for accurate inventory control

-

Software that tracks usage patterns and rotation schedules

-

Integration with production planning systems

Seasonal and Long-Term Storage Considerations

Special attention to long-term storage extends mold life significantly.

Holiday Mold Storage Between Seasons

Seasonal molds spend most of their life in storage and need extra protection:

Enhanced Protection Methods:

-

Double-wrapping for extended storage periods

-

Climate-controlled options for valuable seasonal collections

-

Mid-storage inspection schedules to catch developing issues

-

Detailed inventory systems with condition notes

Seasonal Preparation Timeline:

-

Remove from storage 2-3 weeks before needed for inspection

-

Test seasonal molds with small chocolate batches before full production

-

Plan replacement orders based on condition assessment

-

Document storage location for next season while packing

Specialized Storage for Antique and Collectible Molds

Vintage and collectible molds require conservation-level care:

Preservation Techniques:

-

Acid-free archival materials for all wrapping

-

Individual custom-fitted cases for rare molds

-

Documentation of provenance and condition

-

Minimal handling protocols

Environmental Controls:

-

Stricter humidity and temperature controls (40-60°F, 35-45% RH)

-

Light exposure elimination

-

Vibration minimization

-

Regular conservation assessment

Digital Inventory Systems for Large Collections

Managing extensive mold collections requires digital assistance:

Inventory Management Components:

-

Photographic documentation of each mold

-

Condition tracking over time

-

Usage history recording

-

Replacement cycle planning

-

Location tracking within storage systems

Implementation Options:

-

Spreadsheet systems for small to medium collections

-

Database software for larger inventories

-

Commercial chocolate production software with mold tracking

-

Cloud-based systems with mobile access for real-time updates

Conclusion: Investing in Proper Mold Storage

Proper storage of chocolate molds represents one of the most cost-effective investments a chocolatier can make. By protecting these precision tools from environmental damage, physical harm, and premature wear, you extend their usable life significantly, often transforming a one-year tool into a decade-long asset.

Beyond the financial benefits, well-maintained molds consistently produce higher quality chocolates with better surface finish, cleaner details, and more reliable release properties. This directly impacts your customer experience and product perception, whether you're making chocolates commercially or for friends and family.

By implementing the storage techniques outlined in this guide, you create a foundation for chocolate success that complements your ingredient selection, tempering technique, and artistic vision. Remember that each mold represents not just its purchase cost, but the potential for creating thousands of perfect chocolate pieces over its lifetime—making proper storage an essential practice for every serious chocolate maker.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.