Key Takeaways

-

The right chocolate making machine significantly impacts product quality, production efficiency, and business profitability

-

For small businesses, tempering machines, enrobers, and moulding equipment offer the best balance of quality and affordability

-

Top factors to consider include production capacity, space requirements, maintenance needs, and budget constraints

-

Semi-automatic machines provide the best value for most small chocolate businesses

-

Quality chocolate making equipment is an investment that typically pays for itself within 1-2 years

-

Explore Zucchero Canada's machine collection for high-quality chocolate making equipment suited for small businesses

Introduction: Why Choosing the Right Chocolate Making Machine Matters

Starting or expanding a small chocolate business comes with numerous decisions, but perhaps none is more critical than selecting the right chocolate making machine. Your equipment choices will directly impact your product quality, production capacity, operational efficiency, and ultimately, your bottom line.

The perfect chocolate making machine for your small business isn't necessarily the most expensive or feature-rich option on the market. Rather, it's the equipment that best aligns with your specific business needs, production goals, and growth trajectory. Whether you're crafting artisanal bonbons, producing chocolate bars, or creating chocolate-coated confections, the machinery you select will become the backbone of your operation.

In this comprehensive guide, we'll explore the best chocolate making machines for small businesses across various categories, examine crucial factors to consider before purchasing, and provide expert recommendations to help you make an informed decision. We'll focus specifically on the unique needs of small-scale producers who require professional-grade equipment that doesn't demand industrial-level investment.

Understanding Different Types of Chocolate Making Machines

Before diving into specific recommendations, it's essential to understand the various types of chocolate making machines available and how they fit into the chocolate production process. Each machine serves a distinct purpose in transforming raw chocolate into finished confections.

Chocolate Melters and Warmers

At the beginning of most chocolate production processes is the melting phase. Chocolate melters and warmers are designed to:

-

Melt chocolate to precise temperatures

-

Maintain consistent temperature throughout production

-

Keep chocolate in a workable state for extended periods

Best for: Small businesses that purchase pre-tempered chocolate or use chocolate primarily as an ingredient rather than as a finished product.

Production capacity: Typically 2-15kg, perfect for small batch production.

Price range: $300-$1,500 for quality small business models.

Chocolate Tempering Machines

Tempering is a critical process that gives chocolate its glossy appearance, satisfying snap, and stable structure. Tempering machines:

-

Heat chocolate to precise temperatures to break down existing crystal structures

-

Cool chocolate to promote formation of stable beta crystals

-

Maintain chocolate at the ideal working temperature

Best for: Any business producing finished chocolate products like bars, bonbons, or chocolate-covered confections.

Production capacity: Small business models typically handle 2-30kg.

Price range: $800-$5,000 for quality small business tempering machines.

Chocolate Enrobers

Enrobers automate the process of coating confections with chocolate, offering:

-

Consistent coating thickness

-

Higher production efficiency

-

Professional appearance for coated products

Best for: Businesses specializing in chocolate-coated products like truffles, cookies, nuts, or fruit.

Production capacity: Small business models can coat 5-20kg of product per hour.

Price range: $3,000-$12,000 for entry-level to mid-range enrobers suitable for small businesses.

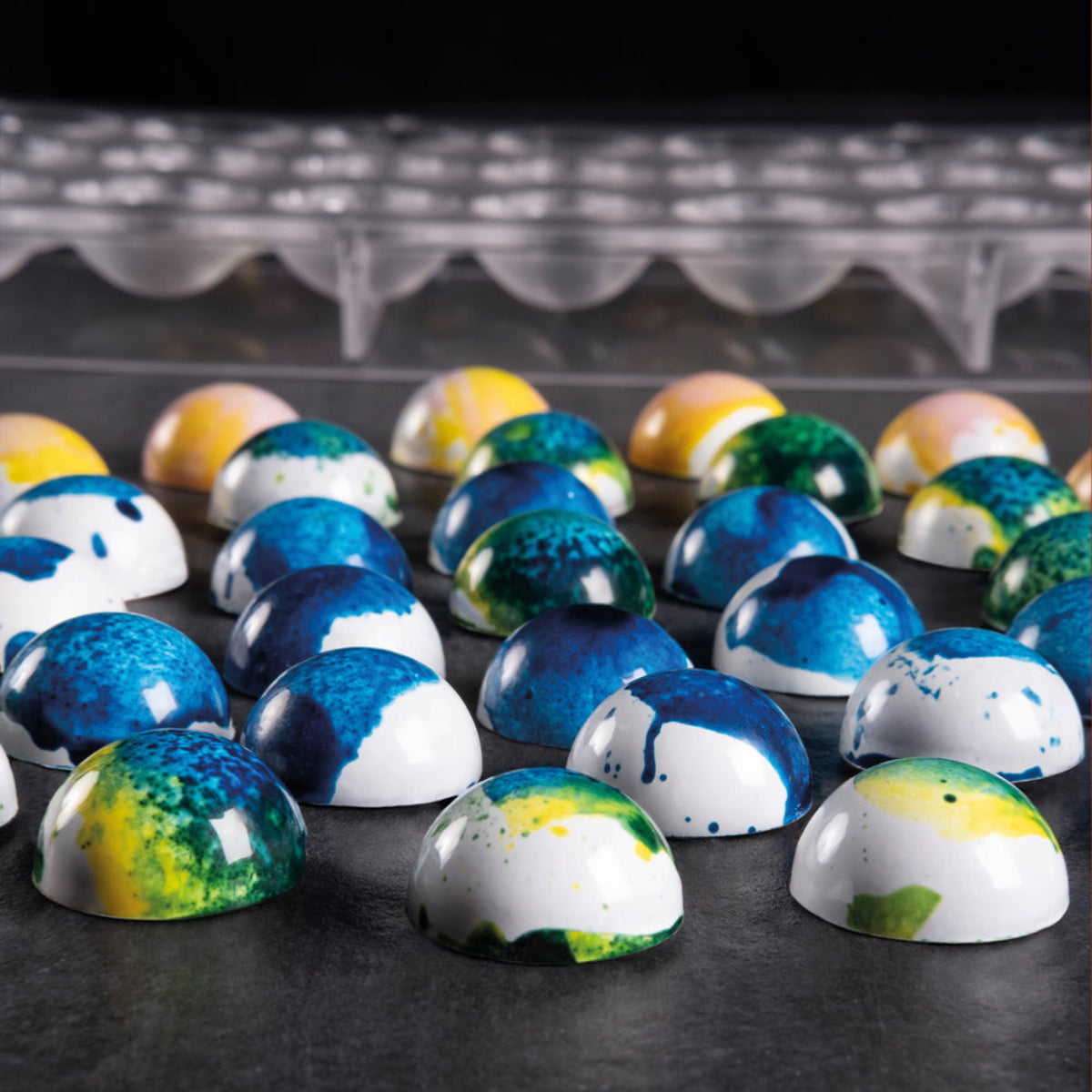

Chocolate Moulding Equipment

For businesses creating shaped chocolate products, moulding equipment is essential:

-

Chocolate mould fillers distribute tempered chocolate into moulds

-

Vibration tables remove air bubbles from moulded chocolate

-

Cooling tunnels or refrigeration units set moulded chocolate properly

Best for: Businesses producing chocolate bars, shaped bonbons, or moulded chocolate figures.

Production capacity: Varies widely based on specific equipment.

Price range: $500-$8,000 depending on the level of automation.

Chocolate Refiners and Conching Machines

For businesses making chocolate from scratch rather than working with premade couverture:

-

Refiners reduce the particle size of chocolate ingredients

-

Conching machines develop flavor and smooth texture

Best for: Bean-to-bar operations or businesses focused on creating proprietary chocolate blends.

Production capacity: Small business models typically process 5-50kg batches.

Price range: $2,000-$15,000 for small-scale refining and conching equipment.

Top Factors to Consider When Choosing a Chocolate Making Machine

Selecting the right chocolate making machine requires careful consideration of several key factors. These considerations will help you narrow down your options and identify equipment that aligns with your specific business needs.

Production Volume and Capacity

The volume of chocolate you plan to produce should directly inform your equipment choices:

-

Micro operations (under 10kg weekly): Consider smaller, manual or semi-automatic equipment

-

Small businesses (10-50kg weekly): Semi-automatic machines offer the best balance of efficiency and investment

-

Growing operations (50-200kg weekly): Look for machines with higher capacity and throughput

-

Scaling businesses (200kg+ weekly): Consider fully automatic systems with continuous production capabilities

Remember to account for seasonal fluctuations and growth projections when estimating your production needs.

Available Space and Facility Considerations

Chocolate production requires adequate space not just for equipment, but for workflow and ancillary processes:

-

Measure your available production space carefully

-

Consider ceiling height for taller equipment

-

Factor in clearance space for operation and maintenance

-

Ensure proper electrical capacity and outlets

-

Verify that your space can maintain appropriate temperature and humidity

For small businesses, compact equipment that serves multiple functions can maximize limited space.

Ease of Use and Training Requirements

Equipment complexity can significantly impact operations, especially in businesses with multiple staff members:

-

Simpler machines require less training and reduce the risk of operator error

-

More complex equipment may offer greater functionality but typically demands more skilled operators

-

Consider the technical aptitude of your team

-

Factor in training time when implementing new equipment

User-friendly interfaces and comprehensive documentation can make a substantial difference in daily operations.

Maintenance and Cleaning Considerations

Chocolate making machines require regular cleaning and maintenance to ensure food safety and optimal performance:

-

Machines with fewer parts or easily disassembled components are typically easier to clean

-

Consider whether parts are dishwasher-safe or require manual cleaning

-

Check the accessibility of areas that come in contact with chocolate

-

Research the availability of replacement parts and service technicians

-

Look for machines with self-cleaning functions if your budget allows

The time spent on daily cleaning and maintenance should be factored into your production schedule and labor costs.

Budget and Return on Investment

While budget constraints are a reality for most small businesses, it's important to consider the total cost of ownership rather than just the initial purchase price:

-

Higher-quality machines typically last longer and require fewer repairs

-

More efficient equipment can reduce labor costs and increase production capacity

-

Energy-efficient models may cost more upfront but save money over time

-

Consider financing options or leasing for higher-end equipment

-

Calculate ROI based on increased production capacity and efficiency

For most small chocolate businesses, quality equipment pays for itself within 1-2 years through improved efficiency and product quality.

Best Chocolate Making Machines for Different Small Business Types

Different chocolate business models have distinct equipment needs. Here's a breakdown of the best machines for various small business operations.

For Artisan Chocolatiers and Bonbon Specialists

Artisan chocolatiers focusing on handcrafted bonbons and filled chocolates typically need:

Primary equipment:

-

Tempering machine: ChocoVision Revolation Delta or Selmi Tempering Machine One

-

Vibration table: Small tabletop model, such as the ChocoVibration or similar

-

Warming cabinet: For maintaining filled chocolates at ideal temperatures

Secondary equipment:

-

Airbrush system for cocoa butter decoration

-

Transfer sheet applicator

-

Cooling cabinet with humidity control

For Chocolate Bar Producers

Businesses focusing on chocolate bars need equipment optimized for moulding and packaging:

Primary equipment:

-

Tempering machine: Selmi Tempering Machine One or Chocovision Revolation X3210

-

Depositor: Semi-automatic bar moulder or depositor

-

Cooling tunnel: Compact cooling system for setting bars quickly

Secondary equipment:

-

Wrapper or packaging equipment

-

Inclusion mixer for bars with nuts, fruit, etc.

-

Storage racks for finished inventory

For Chocolate-Coated Confectionery Businesses

Operations specializing in chocolate-covered nuts, fruits, cookies, or similar products should prioritize:

Primary equipment:

-

Tempering machine: Larger capacity model like the Selmi Tempering Machine Plus

-

Enrober: Entry-level model such as the Hilliard's Mini Enrober or Selmi Mini Enrober

-

Cooling tunnel: To set chocolate coatings efficiently

Secondary equipment:

-

Tumbling system for dragées or panned chocolates

-

Specialized coating tools for hand-dipped items

-

Packaging equipment suited to your specific products

For Bean-to-Bar Chocolate Makers

Bean-to-bar operations have more extensive equipment needs for processing cacao into finished chocolate:

Primary equipment:

-

Roaster: Specialty cocoa bean roaster or adapted coffee roaster

-

Cracker and winnower: For removing shells from roasted beans

-

Grinder/refiner: Melanger like the Premier Wonder Grinder or CocoaTown ECGC-12SL

-

Tempering machine: Any of the previously mentioned options

Secondary equipment:

-

Moulding equipment for bars

-

Packaging systems

-

Aging cabinet for developing flavors

Top Recommended Chocolate Making Machines for Small Businesses

Based on performance, reliability, value, and suitability for small business operations, here are the top machines in each category:

Best Tempering Machines for Small Chocolate Businesses

-

ChocoVision Revolation Delta

-

Capacity: 1.5-7kg

-

Key features: Automatic tempering cycle, compact footprint, easy cleaning

-

Best for: New businesses and artisan chocolatiers with limited space

-

Price range: $1,200-$1,800

-

Selmi Tempering Machine One

-

Capacity: 5-12kg

-

Key features: Continuous tempering, vibration system, precise temperature control

-

Best for: Growing businesses with moderate production needs

-

Price range: $4,000-$5,500

-

FBM Aura 3

-

Capacity: 3-12kg

-

Key features: User-friendly interface, consistent results, renowned reliability

-

Best for: Professional chocolatiers seeking equipment with long lifespan

-

Price range: $3,500-$5,000

Best Enrobers for Small Chocolate Businesses

-

Hilliard's Mini Enrober

-

Capacity: Up to 15kg per hour

-

Key features: Compact design, adjustable curtain flow, customizable belt speed

-

Best for: Businesses transitioning from hand-dipping to automated coating

-

Price range: $5,000-$7,000

-

Selmi Mini Enrober

-

Capacity: Up to 30kg per hour

-

Key features: Removable curtain and tail cutter, vibration system, excellent coverage

-

Best for: Growing businesses with diverse product lines

-

Price range: $8,000-$11,000

-

ChocoMa Enrobing Line

-

Capacity: 20-50kg per hour

-

Key features: Modular design, integration with cooling tunnel, customizable configurations

-

Best for: Established businesses scaling up production

-

Price range: $12,000-$18,000

Best Melters and Warmers for Small Chocolate Businesses

-

Chocolate World Thermalizer

-

Capacity: 5.5-22kg depending on model

-

Key features: Digital temperature control, stainless steel construction, bain-marie system

-

Best for: Versatile use in various chocolate applications

-

Price range: $800-$1,800

-

Mol d'Art Thermalizer

-

Capacity: 4-16kg

-

Key features: Programmable temperature settings, energy-efficient design

-

Best for: Precise temperature control for delicate applications

-

Price range: $700-$1,500

-

Prefamac Chocolate Melter

-

Capacity: 5-30kg depending on model

-

Key features: Multiple compartments, individual temperature control, space-efficient design

-

Best for: Businesses working with multiple chocolate types simultaneously

-

Price range: $1,200-$2,500

Financing Your Chocolate Making Equipment

Quality chocolate making machines represent a significant investment for small businesses. Here are strategies to help finance your equipment:

-

Equipment loans: Many banks offer specific loans for business equipment with favorable terms

-

Equipment leasing: Allows you to access higher-end equipment with lower initial outlay

-

SBA loans: Small Business Administration loans often offer competitive rates for equipment financing

-

Supplier financing: Some equipment suppliers offer payment plans or financing options

-

Crowdfunding: Particularly viable for unique or artisanal chocolate concepts

-

Phased investment: Start with essential equipment and reinvest profits in additional machinery as you grow

When calculating your budget, remember to account for shipping, installation, training, and any facility modifications required to accommodate new equipment.

Maintenance Tips to Extend the Life of Your Chocolate Making Machine

Proper maintenance not only extends equipment life but also ensures consistent product quality and food safety:

-

Daily cleaning: Develop and strictly follow end-of-day cleaning protocols

-

Temperature monitoring: Regularly verify temperature accuracy with secondary thermometers

-

Mechanical checks: Inspect belts, motors, and moving parts for signs of wear

-

Preventative maintenance: Schedule professional service at recommended intervals

-

Staff training: Ensure all operators understand proper equipment handling

-

Documentation: Keep detailed maintenance logs for each piece of equipment

-

Spare parts: Stock essential replacement parts to minimize downtime

Most manufacturers provide detailed maintenance guidelines specific to their equipment—following these recommendations is crucial for warranty coverage and optimal performance.

Frequently Asked Questions About Chocolate Making Machines

How much should I budget for starting a small chocolate business with professional equipment?

For a small-scale professional setup including basic tempering, moulding, and packaging equipment, budget $10,000-$25,000. A more comprehensive setup with enrobing and additional specialized equipment may require $30,000-$60,000. Many successful businesses start with minimal equipment (under $15,000) and expand as they grow.

What's the difference between continuous and batch tempering machines?

Batch tempering machines process a specific amount of chocolate at once, requiring you to temper new batches as needed. Continuous tempering machines maintain a reservoir of tempered chocolate that you can use and replenish throughout production. Continuous machines are more efficient for higher volume production, while batch machines are often more affordable and suitable for smaller operations.

Can I use domestic appliances instead of professional chocolate making machines?

While you can create chocolate products using adapted domestic equipment, professional chocolate making machines offer precision temperature control, higher capacity, better consistency, and time-saving automation that typically makes them necessary for commercial production. The investment in professional equipment generally pays for itself through improved quality and efficiency.

How much space do I need for a small chocolate production setup?

A minimal professional setup can function in as little as 200-300 square feet, though 500-800 square feet provides more comfortable working conditions for a small team. Remember to account for storage space for ingredients and finished products, packaging areas, and required clearances around equipment.

Is it better to buy new or used chocolate making equipment?

New equipment offers warranty protection, current technology, and predictable performance. Used equipment can represent significant savings but carries higher risk of maintenance issues. If purchasing used, prioritize established brands with good service networks, inspect equipment thoroughly, and if possible, test before buying. For critical production equipment like tempering machines, new is often worth the investment.

How do I ensure my chocolate making machine complies with food safety regulations?

Purchase equipment designed specifically for food production that uses food-safe materials (typically stainless steel and food-grade plastics). Ensure the equipment is easily cleanable and can be properly sanitized. Check that the manufacturer can provide documentation confirming compliance with relevant food safety standards in your region.

Conclusion: Investing in Your Chocolate Business Future

Selecting the right chocolate making machine for your small business is a pivotal decision that will shape your production capabilities, product quality, and operational efficiency for years to come. While the initial investment may seem substantial, quality equipment provides the foundation for creating exceptional chocolate products that command premium prices and build customer loyalty.

Remember that the best equipment choice isn't necessarily the most expensive or feature-rich option, but rather the one that aligns most closely with your specific business model, production needs, and growth plans. By carefully assessing your requirements and researching available options, you can make an informed decision that will serve your business well into the future.

Ready to explore chocolate making machines for your small business? Zucchero Canada offers a curated selection of high-quality chocolate making equipment perfect for small business applications. Their knowledgeable team can help you identify the right machines for your specific needs and provide ongoing support as your business grows.

Investing in the right chocolate making machine today will position your small business for success tomorrow, enabling you to create exceptional chocolate products that delight customers and drive profitability.

Laisser un commentaire

Tous les commentaires sont modérés avant d'être publiés.

Ce site est protégé par hCaptcha, et la Politique de confidentialité et les Conditions de service de hCaptcha s’appliquent.