Creating perfectly coated chocolate products demands equipment that delivers uniform coverage, consistent thickness, and professional appearance across hundreds or thousands of pieces. A chocolate enrobing machine automates this precision through continuous chocolate curtains and controlled conveyor systems, transforming what would be hours of hand-dipping into efficient, repeatable production. The fundamental advantage of an enrober machine lies in its systematic approach where products travel through a flowing chocolate curtain on a temperature-controlled conveyor, receiving complete coverage from all angles while eliminating the inconsistencies inherent in manual dipping and dramatically increasing throughput.

Chocolate Enrobing Systems for Every Production Scale

Compact Tabletop Enrobers

Entry-level tabletop enrobers suit artisan producers and small-scale operations producing limited quantities. These compact units typically feature 150-200mm belt widths capable of coating smaller products efficiently. Despite modest size, quality tabletop models incorporate essential features including temperature-controlled chocolate tanks, adjustable belt speeds, and excess chocolate removal systems. These machines bridge the gap between hand-dipping and full production equipment, offering automation benefits at accessible price points.

Commercial Floor-Standing Models

Mid-range floor-standing enrobers accommodate growing operations requiring higher throughput and greater versatility. Belt widths typically span 250-400mm, allowing simultaneous coating of multiple rows of products. Enhanced features often include bottom coating capabilities, air knives for excess chocolate removal, and cooling tunnels for immediate crystallization. The Enrobing Line 200 mm exemplifies equipment designed for serious commercial production, combining substantial capacity with professional features that ensure consistent results across extended production runs.

Industrial Production Lines

Industrial-scale enrobers serve high-volume manufacturers requiring maximum throughput and automation integration. These systems feature wide belts exceeding 500mm, multiple chocolate curtains for complete coverage, sophisticated temperature controls, and integrated cooling systems. The Enrobing Line CW12 180 mm demonstrates how equipment design can focus on particular production approaches, offering features tailored to specific coating applications. Complete systems like the Enrobing Station Cooling Tunnels integrate multiple production stages into continuous lines that maximize efficiency.

Specialized Coating Equipment

Specialized enrobing equipment addresses specific product categories or production requirements. Some machines excel at bottom-coating applications for items like wafer biscuits or cookie bases, while others optimize for complete submersion coating of irregular shapes. Our comprehensive chocolate enrobing machines collection showcases various capacity options and configurations matching different production needs.

Making the Right Enrobing Equipment Decision

Analyze Your Production Volume Needs

Begin by calculating your typical and peak coating volumes—how many pieces do you need to coat daily during normal operations and during seasonal rushes? This analysis reveals whether compact equipment suffices or if higher-capacity models prevent bottlenecks during critical production periods. Consider not just current needs but realistic growth projections over the next three to five years.

Match Equipment to Your Product Range

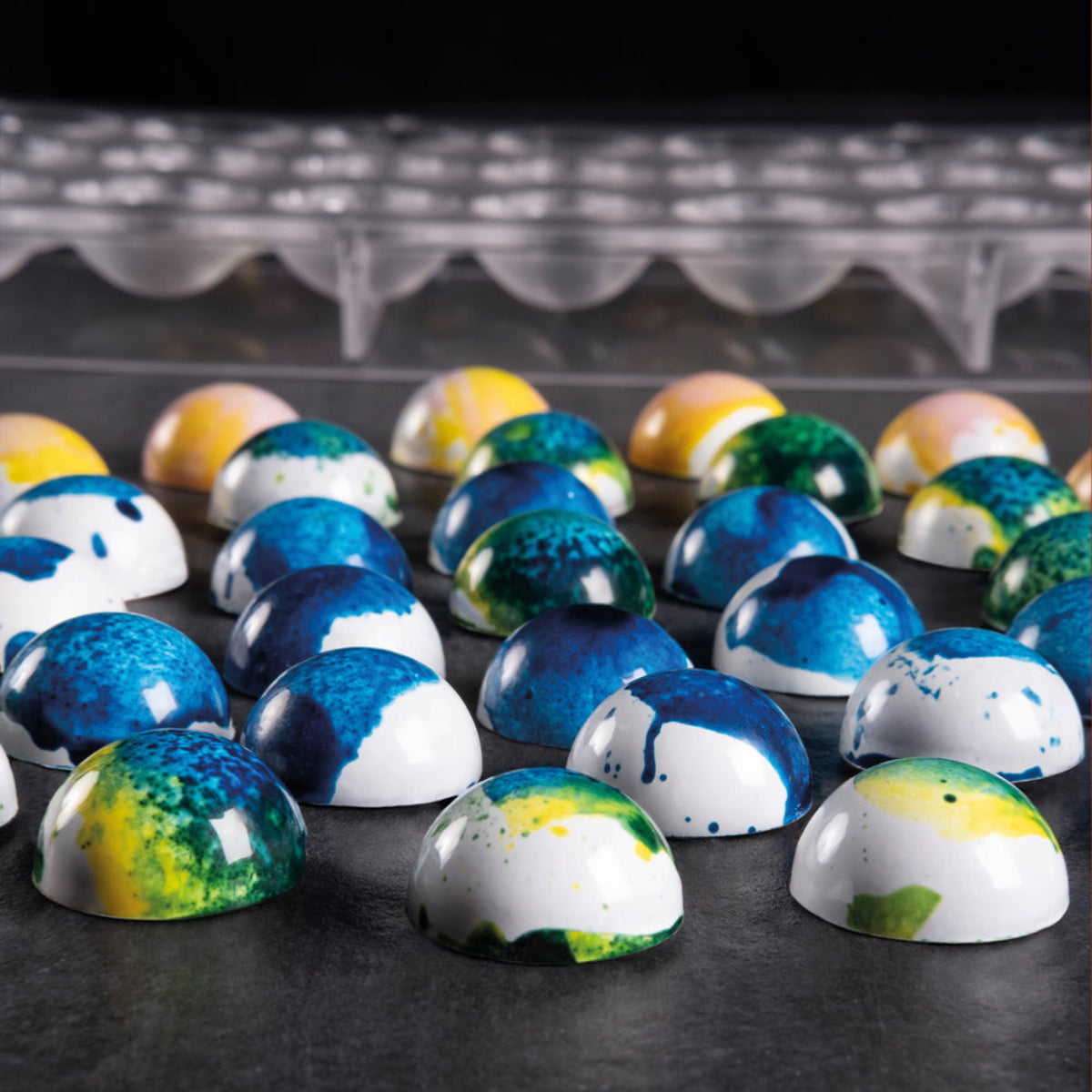

Product characteristics significantly influence equipment selection. Small confections like truffles or bonbons require different belt widths and spacing than larger items like candy bars or biscuits. Consider your widest products when evaluating belt dimensions, as equipment must accommodate your largest items while efficiently handling smaller pieces. The ability to process varied product sizes without major reconfiguration provides valuable operational flexibility as your product range evolves.

Plan Your Production Workflow Integration

Integration with existing equipment influences enrobing machine selection considerably. Consider how enrobed products will cool and crystallize after coating—do you need integrated cooling or will you use separate cooling tunnels or refrigeration? Understanding chocolate tempering techniques helps operators maintain optimal chocolate condition throughout production. The chocolate melting machines you currently use may provide chocolate preparation, but enrobers need consistent supply at proper temperatures throughout operation.

Assess Space and Infrastructure Requirements

Available production space often constrains equipment choices. Measure floor space carefully, accounting for operator access on both loading and unloading sides, plus maintenance clearance around the unit. Tabletop models conserve space but limit capacity, while floor-standing equipment demands dedicated areas but offers superior throughput and ergonomics. Consider vertical space as well, as some enrobers integrate cooling tunnels that extend upward requiring adequate ceiling clearance.

Calculate Total Investment and Operating Costs

Budget considerations extend beyond purchase price to include installation, electrical requirements, and operating costs. Professional enrobing equipment requires specific electrical service, so verify voltage and amperage availability before selecting models. Factor in chocolate usage patterns as enrobers require minimum chocolate volumes to operate effectively, potentially increasing ingredient costs for smaller operations.

Why Professional Enrobing Equipment Transforms Production

Achieve Unmatched Coating Uniformity

Coating uniformity represents the most visible benefit as enrobers apply identical chocolate thickness across every product, creating professional appearance that hand-dipping rarely achieves. This consistency extends beyond aesthetics to portion control, ensuring predictable chocolate usage and accurate cost calculations for each finished piece. Precise temperature control systems maintain chocolate at optimal working viscosity throughout the enrobing process, with multiple temperature zones regulating the main tank, distribution system, and recycling chocolate independently.

Multiply Production Speed and Throughput

Production speed increases exponentially compared to manual methods. Where hand-dipping might coat 50-100 pieces hourly depending on size and complexity, an enrobing machine processes hundreds of pieces in the same timeframe. This acceleration proves crucial during seasonal peaks when order volumes multiply. The continuous operation allows one operator to manage coating while others focus on centers preparation, packaging, or quality control.

Minimize Chocolate Waste and Costs

Chocolate waste reduction improves profitability significantly. Manual dipping generates excess chocolate clinging to tools, dripping during transfer, and accumulating on work surfaces. Enrobers recirculate chocolate continuously, capturing and reusing what would otherwise become waste. The closed-loop system maintains chocolate in temper while minimizing exposure to contaminants, allowing the same batch to coat products throughout extended production runs.

Expand Product Versatility and Range

Product versatility expands with proper enrobing equipment. Beyond simple coating, enrobers handle bottom-coating applications, partial coverage for decorative effects, and multiple passes for thicker chocolate layers. Adjustable chocolate curtain systems allow operators to customize coating characteristics for different products, with curtain height, width, and flow rate adapting to accommodate varying center sizes and desired coating thicknesses.

Reduce Labor Requirements and Costs

Labor cost savings accumulate quickly with automated coating. Enrobing requires minimal supervision once properly set up, with one operator managing the entire process while performing secondary tasks like placing centers on the belt or removing finished products. This efficiency allows smaller teams to produce higher volumes, improving per-unit labor costs while reducing the physical strain of repetitive hand-dipping motions.

Ensure Professional Quality Standards

Vibration and excess chocolate removal mechanisms ensure clean, professional coating appearance. Gentle vibration as products exit the chocolate curtain settles the coating evenly while preventing pooling or thick spots. Air knives or mechanical scrapers remove excess chocolate from product bottoms, creating clean bases that don't stick together. Belt systems using stainless steel mesh or wire allow excess chocolate to drip through and recirculate rather than building up under products.

Elevate Your Chocolate Coating Operations with Zucchero Canada

Implementing chocolate enrobing technology transforms confectionery operations from labor-intensive manual processes into efficient, consistent production systems. The investment in quality enrobing equipment pays returns through increased capacity, reduced labor costs, improved product consistency, and minimized chocolate waste. These benefits compound over time, making professional coating equipment essential for operations committed to growth and market competitiveness.

Success with enrobing equipment extends beyond the machine itself to encompass proper chocolate preparation, temperature management, and technique refinement. Understanding factors like chocolate viscosity, tempering stability, and belt speed optimization ensures you extract maximum value from your equipment investment. Technical support and parts availability deserve consideration as enrobers contain precision components requiring occasional maintenance or replacement.

At Zucchero Canada, we provide professional chocolate enrobing equipment selected for reliability, performance, and value. Our selection accommodates operations from emerging artisan chocolatiers to established commercial manufacturers, ensuring we support businesses at every production scale. Our partnerships with reputable manufacturers ensure long-term support for equipment purchased through our channels.

We invite you to explore our enrobing equipment collection and discover how automated coating technology can elevate your production capabilities. Browse our complete chocolate machines catalog to see complementary equipment that creates complete production lines moving products efficiently from preparation through final packaging.

Our experienced team offers personalized guidance on equipment selection, helping match specific features, capacities, and configurations to your operational requirements and product portfolio. For detailed specifications, capacity assessments, or assistance planning your complete coating workflow including complementary equipment needs, contact our knowledgeable staff who understand both technical requirements and practical realities of professional chocolate production.

Visit zuccherocanada.ca to review our complete chocolate equipment catalog, or reach out directly for expert consultation on your enrobing needs. We're committed to supporting your confectionery success with quality machinery, technical expertise, and ongoing customer service throughout your equipment's operational life.