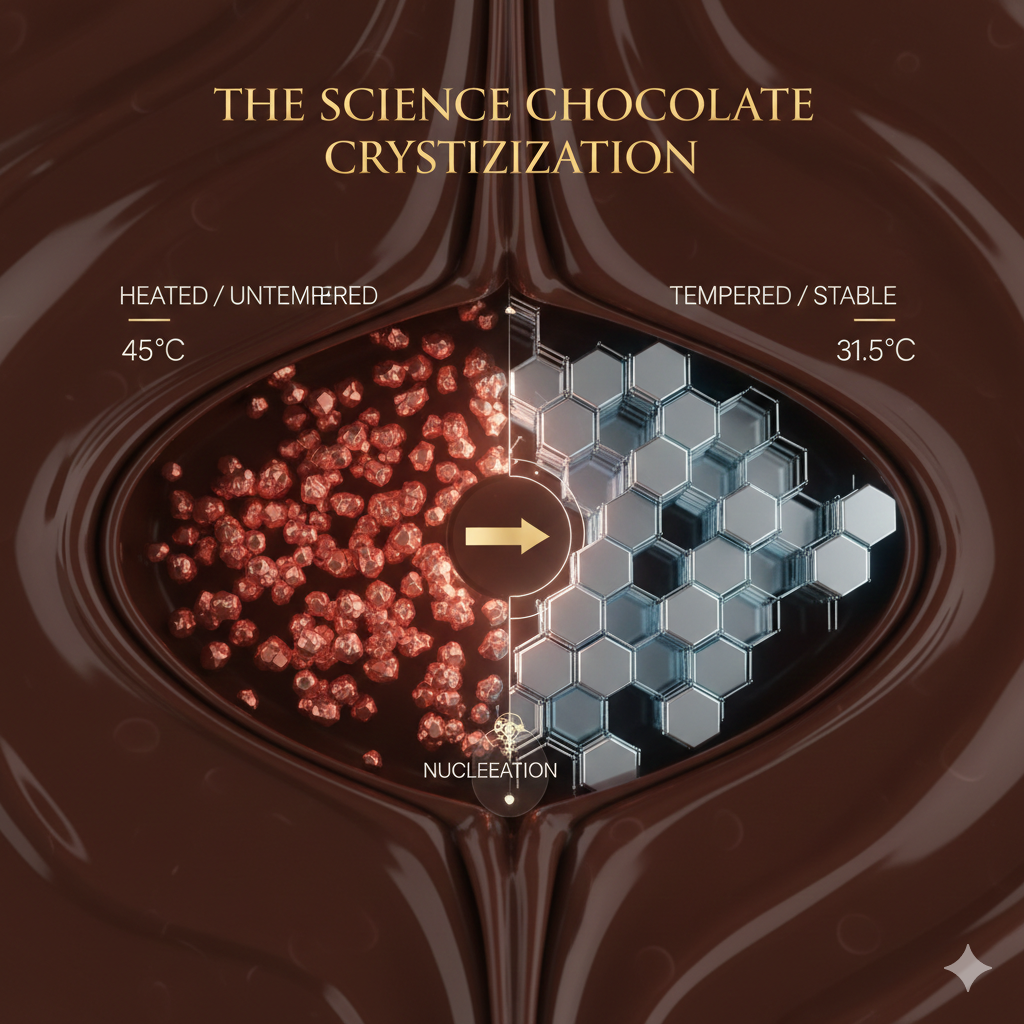

Chocolate crystallization involves controlling cocoa butter's polymorphic crystal formation through precise temperature manipulation, transforming melted chocolate into perfectly tempered product suitable for molding, enrobing, and decorating applications. This comprehensive guide explores the science behind crystal formation, practical tempering methods, and troubleshooting techniques ensuring consistent results across all chocolate applications.

The Science of Chocolate Crystallization

Understanding Cocoa Butter Polymorphs

Cocoa butter forms six distinct crystal types labeled I through VI, each with different melting points and stability characteristics affecting finished chocolate quality. Crystallization aims to produce primarily Form V crystals (also called beta-2), which melt at 93-97°F (34-36°C) and create chocolate's characteristic snap and glossy appearance.

|

Crystal Form |

Melting Point |

Characteristics |

Desirability |

|

Form I |

63°F (17°C) |

Soft, crumbly, melts easily |

Undesirable |

|

Form II |

70°F (21°C) |

Soft, crumbly, poor snap |

Undesirable |

|

Form III |

78°F (26°C) |

Firm but grainy |

Undesirable |

|

Form IV |

82°F (28°C) |

Firm but unstable |

Undesirable |

|

Form V |

94°F (34°C) |

Hard, glossy, good snap |

Target for tempering |

|

Form VI |

97°F (36°C) |

Hard but too stable, grainy over time |

Develops during aging |

Lower forms (I-IV) produce soft, dull chocolate that melts at room temperature and blooms quickly. Form VI develops when chocolate ages or experiences heat cycles, causing fat bloom as unstable Form V transitions into overly stable Form VI. Professional chocolate maintains Form V dominance through proper tempering and storage.

Temperature's Role in Crystal Formation

Temperature control determines which crystal forms develop during crystallization. Heating chocolate above 113°F (45°C) melts all crystals completely, creating blank slate for controlled recrystallization. Cooling to 82-84°F (28-29°C) encourages Form V seed crystal formation while preventing lower unstable forms from dominating.

Dark Chocolate 55% Venezuela demonstrates how quality couverture chocolate responds to proper temperature control, developing excellent snap and shine through correct crystallization. Equipment like professional tempering machines automates temperature curves ensuring ideal crystal formation.

Tempering Methods for Optimal Crystallization

Multiple approaches achieve proper crystallization, each with distinct advantages depending on production scale, chocolate type, and available equipment.

Seeding Method Crystallization

The seeding method introduces stable Form V crystals from solid chocolate into melted chocolate, providing templates encouraging proper crystallization throughout the batch. Melt two-thirds of chocolate to working temperature, then add remaining chopped chocolate gradually while stirring. Solid chocolate's existing Form V crystals "seed" the melted chocolate, propagating stable crystal formation.

|

Chocolate Type |

Melt Temp |

Seed Temp |

Working Temp |

Test Result |

|

Dark (70%+) |

115-120°F (46-49°C) |

82-84°F (28-29°C) |

88-90°F (31-32°C) |

Sets in 3-5 min |

|

Dark (55-69%) |

113-118°F (45-48°C) |

82-84°F (28-29°C) |

88-90°F (31-32°C) |

Sets in 3-5 min |

|

Milk Chocolate |

110-115°F (43-46°C) |

82-84°F (28-29°C) |

86-88°F (30-31°C) |

Sets in 4-6 min |

|

White Chocolate |

105-110°F (40-43°C) |

80-82°F (27-28°C) |

82-84°F (28-29°C) |

Sets in 4-6 min |

This method works reliably for various chocolate types and scales easily from small batches to commercial production. Venezuelan Blend 55% Sticks provide convenient pre-portioned seed chocolate.

Tabling Method for Professional Results

Tabling involves pouring two-thirds of melted chocolate onto marble or granite surface, spreading and scraping repeatedly until temperature drops and chocolate thickens from crystallization. This physical agitation encourages Form V development while dispersing heat rapidly. Scrape thickened chocolate back into remaining melted chocolate, mixing thoroughly and reheating gently to working temperature.

Professional chocolatiers use marble surfaces with quality spatulas and scrapers for precise temperature control during tabling. This traditional method provides excellent crystallization control though requires practice and physical effort unsuitable for large production volumes.

Automated Tempering Systems

Automated tempering machines control crystallization through programmed temperature curves eliminating manual monitoring. Professional tempering machines maintain precise temperatures while agitating chocolate continuously, producing consistent Form V crystals. Our machines collection includes equipment handling substantial volumes with minimal operator intervention.

These systems monitor chocolate temperature constantly, adding heat or cooling as needed while maintaining ideal conditions for crystallization. Professional equipment suits operations requiring reliable tempering throughout production days.

Testing Crystallization Quality

Verifying proper crystallization before proceeding with production prevents costly mistakes and wasted chocolate.

The Temper Test

Spread small amount of tempered chocolate on parchment paper or clean spatula blade. Properly crystallized chocolate sets within 3-5 minutes at room temperature (68-72°F/20-22°C), developing slight matte finish that becomes glossy as crystallization completes. The set chocolate should snap cleanly when bent, demonstrating Form V crystal dominance.

Chocolate that remains soft after 5 minutes or develops streaky, dull appearance indicates improper crystallization. Re-temper the batch before using for molding, enrobing, or other applications requiring stable chocolate.

Temperature Monitoring Tools

Accurate temperature measurement proves essential for crystallization success. Digital thermometers with immersion probes provide precise readings throughout tempering process. Infrared thermometers enable non-contact temperature verification useful when checking chocolate in molds or on cooling tables.

Professional operations maintain multiple thermometers verifying accuracy through comparison. Even small temperature errors of 2-3°F affect crystallization significantly, producing unreliable results despite seemingly proper technique.

Applications Requiring Proper Crystallization

Understanding crystallization importance varies by application, with some techniques demanding perfect temper while others tolerate relaxed standards.

Molding Applications

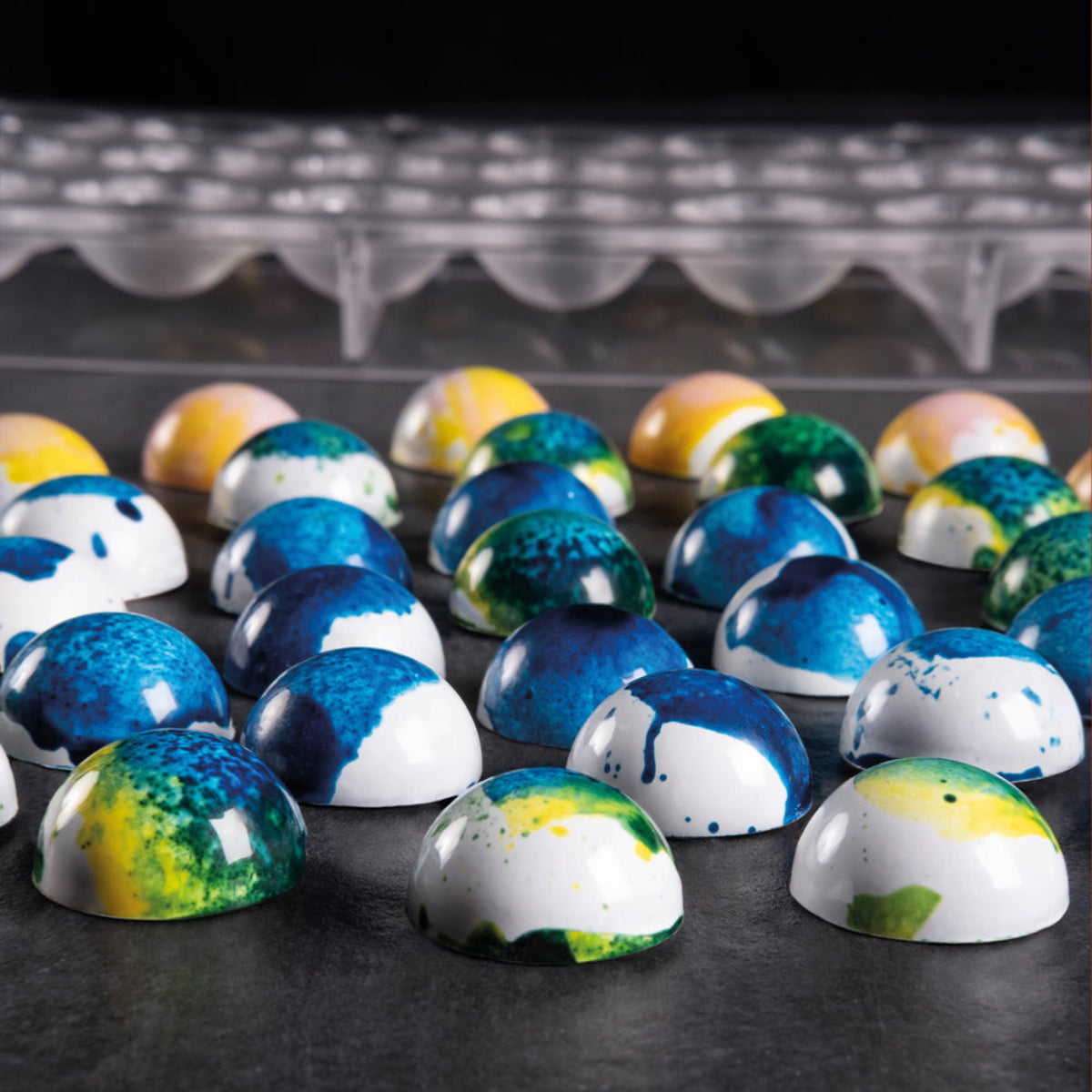

Molded chocolates require excellent crystallization for clean release and professional appearance. Professional chocolate molds produce intricate designs capturing every detail only when properly tempered chocolate contracts uniformly during crystallization. Poor temper causes sticking, dull finish, and potential bloom development within days.

Both polycarbonate molds and silicone molds benefit from proper crystallization though flexible silicone forgives minor tempering imperfections through easier release. Our 3D seasonal molds showcase how proper crystal formation captures dimensional details.

Enrobing and Coating

Enrobing operations demand consistent crystallization maintaining proper viscosity while producing uniform coatings. Professional enrobing equipment works optimally when chocolate maintains stable Form V crystals throughout coating process. Temperature fluctuations during enrobing disrupt crystallization causing thickness variations and appearance defects.

Decorative Work and Finishing

Chocolate decoration using colored cocoa butter requires understanding crystallization in both the cocoa butter colors and base chocolate. Professional color ranges perform best when applied to properly crystallized chocolate bases. Spray applications using professional equipment depend on proper crystallization in both spray material and receiving surface.

Troubleshooting Crystallization Problems

Bloom Development Issues

Fat bloom indicates improper crystallization or storage temperature fluctuations causing Form V crystals to transition into Form VI. The white, streaky appearance results from cocoa butter separating and recrystallizing on chocolate surfaces. Prevent fat bloom through proper tempering and stable storage temperatures between 60-65°F (15-18°C).

Sugar bloom differs from fat bloom but also indicates crystallization environment problems. Excessive humidity causes surface sugar dissolution and recrystallization creating grainy white coating. Store properly crystallized chocolate at ideal humidity levels preventing moisture-related defects. Learn more in our guide on how to avoid chocolate bloom.

Soft or Sticky Chocolate

Chocolate remaining soft at room temperature indicates insufficient Form V crystal development during crystallization. This occurs when chocolate wasn't cooled adequately during tempering or working temperature was too high encouraging unstable crystal forms. Re-temper the batch following proper temperature curves ensuring adequate seeding or agitation.

Streaky or Dull Finish

Uneven crystallization produces streaky appearance or dull finish lacking professional gloss. This results from inconsistent temperatures within the chocolate mass during crystallization. Stir chocolate thoroughly during tempering ensuring uniform temperature throughout, and maintain working temperature consistently when filling molds or coating products.

Advanced Crystallization Techniques

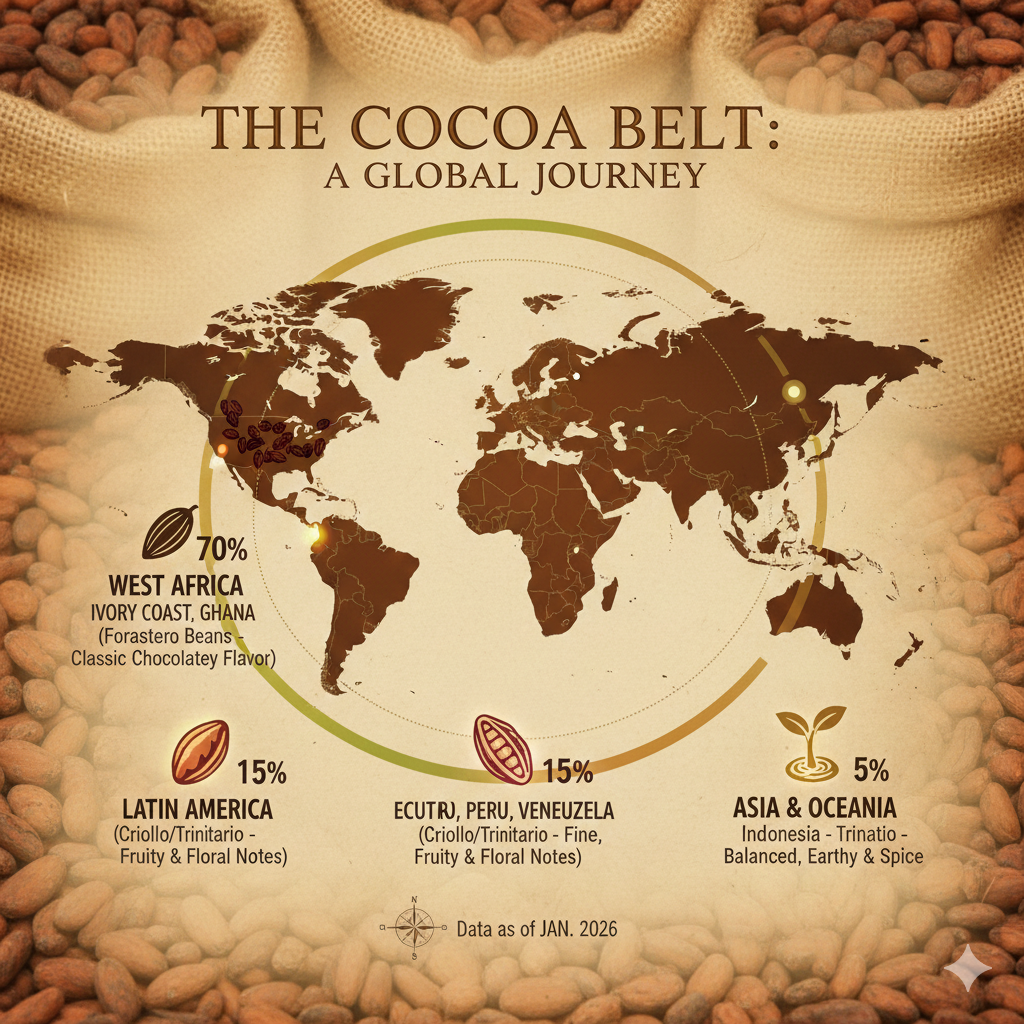

Working with Single-Origin Chocolates

Single-origin chocolates like Venezuelan varieties may exhibit unique crystallization characteristics based on cocoa butter composition. Fine flavor cacao from regions like Venezuela or Peru sometimes requires temperature curve adjustments reflecting specific cocoa butter profiles.

Test each new chocolate source establishing optimal tempering parameters. Document successful temperatures and techniques for bean-to-bar operations using varied cacao origins throughout the year. Our fine chocolate collection showcases premium single-origin options.

Temperature Maintenance During Production

Maintaining proper crystallization throughout extended production sessions requires temperature discipline. Use chocolate melters maintaining consistent working temperatures without overheating. Climate-controlled work surfaces prevent chocolate temperature drift during hand work.

Monitor chocolate temperature frequently during production, adjusting heat sources maintaining optimal working temperature. Even properly tempered chocolate loses ideal crystallization when held too warm for extended periods, requiring re-tempering before use.

Conclusion

Mastering chocolate crystallization through proper tempering techniques separates amateur chocolate work from professional-quality confections exhibiting perfect snap, glossy finish, and excellent stability. Success requires understanding cocoa butter's polymorphic behavior, maintaining precise temperatures throughout tempering, and verifying proper Form V crystal development before production. Whether creating molded chocolates, enrobed confections, or decorative elements, proper crystallization ensures products meet professional standards while resisting bloom and maintaining quality during storage. Explore professional tempering equipment, premium chocolate varieties, and precision temperature monitoring tools at Zucchero Canada to master chocolate crystallization producing consistently excellent results across all applications.

References

Beckett, S. T. (2023). The science of chocolate (3rd ed.). Royal Society of Chemistry.

Greweling, P. (2023). Chocolates and confections: Formula, theory, and technique for the artisan confectioner (3rd ed.). John Wiley & Sons.

KREA Swiss. (2024). Professional food equipment for chocolate production. https://kreaswiss.com/food-equipment

Pavoni Italia. (2024). Professional color collections for chocolate work. https://pavonitalia.com/en/collections/professional-collezioni-colori-e-materie-prime

Talbot, G. (2024). Chocolate temper and crystallization science. In Science and Technology of Enrobed and Filled Chocolate. Woodhead Publishing.

Laisser un commentaire

Tous les commentaires sont modérés avant d'être publiés.

Ce site est protégé par hCaptcha, et la Politique de confidentialité et les Conditions de service de hCaptcha s’appliquent.