Creating chocolate hearts with silicone molds produces romantic confections perfect for Valentine's Day, weddings, anniversaries, and heartfelt gifts throughout the year. This comprehensive guide reveals professional methods for crafting bakery-quality heart chocolates using flexible silicone molds, optimal tempering approaches, and creative decoration that elevates homemade confections to artisan standards.

Understanding Silicone Molds for Chocolate Hearts

Silicone molds offer distinct advantages for chocolate work, with flexibility, heat resistance, and natural non-stick properties that simplify chocolate release compared to rigid polycarbonate alternatives.

Advantages of Silicone for Heart Shapes

Silicone molds offer distinct benefits when learning to make chocolate hearts. The flexible material releases chocolates with gentle pressure, reducing breakage risk especially important for delicate heart shapes with pointed tips. Silicone withstands temperature extremes from freezing to 450°F (232°C), accommodating both chocolate setting and cleanup procedures without material degradation.

The Heart Silicone Jelly Mold 24 Cavities demonstrates silicone's versatility for chocolate hearts, producing multiple pieces simultaneously. Unlike rigid molds requiring perfect temper for release, silicone forgives minor tempering imperfections through its flexibility. This forgiveness makes silicone ideal for beginners mastering chocolate heart techniques.

Selecting Heart Mold Designs

Heart mold designs range from classic symmetrical shapes to contemporary asymmetric styles. Three-dimensional molds offer depth creating impressive chocolates, while simpler flat designs suit filled chocolates and bark applications.

|

Mold Style |

Best Applications |

Skill Level |

|

Flat Hearts |

Bark, topped chocolates |

Beginner |

|

3D Hearts |

Hollow chocolates, centerpieces |

Intermediate |

|

Multi-Cavity |

Production, gifts |

All levels |

|

Mini Hearts |

Garnishes, decorations |

Beginner |

Consider cavity depth when selecting mold designs. Shallow cavities suit solid chocolates and bonbons, while deeper cavities accommodate filled centers or hollow construction. Our silicone molds for pastry and chocolate collection provides varied depths within single molds enabling diverse chocolate heart production.

Essential Materials and Equipment

Professional chocolate hearts require quality chocolate, properly prepared molds, and tools facilitating smooth production workflow.

Chocolate Selection for Silicone Molds

Chocolate hearts achieve best results with properly tempered chocolate or quality compound coating. Couverture chocolate containing minimum 31% cocoa butter delivers superior snap and glossy finish when tempered correctly. Dark Chocolate 55% Venezuela provides rich flavor perfect for romantic chocolate hearts, while FCH White Chocolate Latin American Origin 28% offers a canvas for coloring and decoration.

Compound chocolate made with vegetable oils eliminates tempering requirements, ideal for beginners learning to make chocolate hearts with silicone molds. White Chocolate Candy Melts 5kg provide an economical option for large-batch production.

Ruby chocolate creates stunning pink chocolate hearts without artificial coloring. The natural berry flavor complements romantic themes perfectly. For artisan quality, consider single-origin options offering distinctive flavor profiles.

Required Tools and Supplies

Creating professional chocolate hearts demands specific equipment beyond basic kitchen tools. A digital thermometer ensures accurate temperature monitoring during tempering, while soft plastic scrapers remove excess chocolate without damaging flexible molds.

Professional melting equipment maintains consistent chocolate temperature. The Meltinchoc Chocolate Melter Multi-Tank 3L accommodates multiple chocolate types simultaneously, perfect when creating hearts in various colors or flavors.

Additional supplies include parchment paper, cooling racks, and storage containers maintaining optimal conditions for finished chocolate hearts.

Preparing Silicone Molds Properly

Cleaning and Conditioning

Wash new silicone molds thoroughly with warm soapy water removing manufacturing residues before first use. Rinse completely and dry with lint-free cloth or air-dry inverted on clean towel. Any moisture causes chocolate to seize and develop white spots ruining finished appearance.

Polish mold cavities with soft cotton cloth removing any dust or fingerprints. While silicone naturally resists sticking, cleanliness dramatically affects finished chocolate quality. Avoid using oil, cooking spray, or other release agents with chocolate; these substances create cloudy film on chocolate surfaces and affect flavor negatively.

Between uses, wash molds in warm soapy water, rinse thoroughly, and dry completely before storage. Store silicone molds flat or hanging in clean, dry location preventing dust accumulation. Inspect molds periodically for tears or degradation, replacing damaged ones that affect quality.

Temperature Considerations

Room temperature silicone molds work best for chocolate heart production. Cold molds cause chocolate to set too quickly creating thick shells and poor detail capture, while warm molds prevent proper crystallization. Allow molds to equilibrate to workspace temperature approximately 65-70°F (18-21°C) before use.

Some chocolatiers chill silicone molds briefly before pouring chocolate, accelerating setting for production efficiency. This technique works with compound chocolate but risks improper temper crystallization with couverture chocolate.

Chocolate Tempering for Silicone Molds

Properly tempered chocolate creates hearts that snap cleanly, exhibit glossy finish, and resist bloom during storage.

Tempering Methods Comparison

Chocolate hearts benefit from proper tempering despite silicone's forgiving nature. The seeding method adds unmelted chocolate to melted chocolate, introducing stable crystals throughout the mixture. Melt two-thirds chocolate to appropriate temperature, add remaining chocolate gradually while stirring until temperature drops, then gently reheat to working temperature.

|

Chocolate Type |

Melting Temp |

Cooling Temp |

Working Temp |

Silicone Benefits |

|

Dark Chocolate |

115-120°F (46-49°C) |

82-84°F (28-29°C) |

88-90°F (31-32°C) |

Flexible release aids demolding |

|

Milk Chocolate |

110-115°F (43-46°C) |

82-84°F (28-29°C) |

86-88°F (30-31°C) |

Gentler handling prevents damage |

|

White Chocolate |

105-110°F (40-43°C) |

80-82°F (27-28°C) |

82-84°F (28-29°C) |

Reduced breakage risk |

Test temper by spreading small amount on parchment; properly tempered chocolate sets within 3-5 minutes with slight matte finish. Professional tempering machines automate this process for consistent production. For compound chocolate, simply melt to 95-100°F (35-38°C) without tempering requirements.

Working With Untempered Chocolate

Compound chocolate offers a simplified approach for beginners. Melt gently to 95-100°F (35-38°C), avoiding excessive heat that damages vegetable oils. Compound chocolate sets quickly in silicone molds without refrigeration, producing hearts ready for demolding within 20-30 minutes.

While compound chocolate lacks tempered chocolate's snap and glossy finish, silicone's flexibility compensates somewhat by releasing chocolates easily regardless of crystal structure. This makes compound chocolate an excellent choice for learning chocolate heart techniques before progressing to more demanding tempered chocolate work.

Step-by-Step Molding Process

Creating Solid Heart Chocolates

Pour tempered or melted chocolate into silicone mold cavities until slightly overfilled for solid hearts. Tap mold firmly on counter 15-20 times releasing air bubbles that create holes in finished surfaces. Use a scraper removing excess chocolate from mold surface, creating flat backing enabling hearts to sit upright.

Allow chocolate to crystallize completely before demolding. Tempered chocolate in silicone typically sets at room temperature in 30-45 minutes, though refrigeration accelerates process to 15-20 minutes if needed. Chocolate contracts slightly during setting, naturally releasing from flexible silicone. When chocolate develops a satin finish and edges appear slightly separated from mold walls, hearts are ready for removal.

Invert mold over clean surface and flex gently coaxing chocolates to release. Apply gentle pressure to mold back near each cavity encouraging hearts to drop out cleanly without forcing that risks breakage.

Making Hollow Heart Shells

Hollow chocolate hearts require coating technique building shells through multiple layers. Pour chocolate into cavities, then immediately invert mold allowing excess to drain back into bowl. Rotate mold during draining ensuring even coating across all interior surfaces. Use a soft scraper removing excess from mold surface.

Allow first coat to set until tacky but not fully hard, approximately 5-8 minutes. Apply second coating using same method, building shell thickness to desired strength. Two thin coats create stronger shells than single thick layer. For filled chocolate hearts, apply third coat after positioning filling to create sealed compartment.

Three-dimensional mold options work beautifully for hollow construction, their depth accommodating substantial fillings. Once final coat crystallizes completely, flex mold gently releasing hollow chocolate hearts ready for filling or presentation.

Adding Fillings and Layers

Filled chocolate hearts incorporate ganache, caramel, or fruit preparations between chocolate layers. Create chocolate base and walls as described above, allow to set until firm, then pipe filling using pastry bags. Leave slight gap at top for sealing chocolate layer preventing filling from touching mold surface where it would show.

Chill filled hearts briefly to firm filling before applying final chocolate layer. This prevents filling from mixing with sealing chocolate or creating bubbles. Pour chocolate over filling and scrape level with mold surface.

Allow complete crystallization before demolding filled pieces. The additional weight and moisture from filling requires extra setting time compared to solid hearts. Patience during this stage prevents cracking and filling leakage that ruins finished appearance.

Creative Decoration Techniques

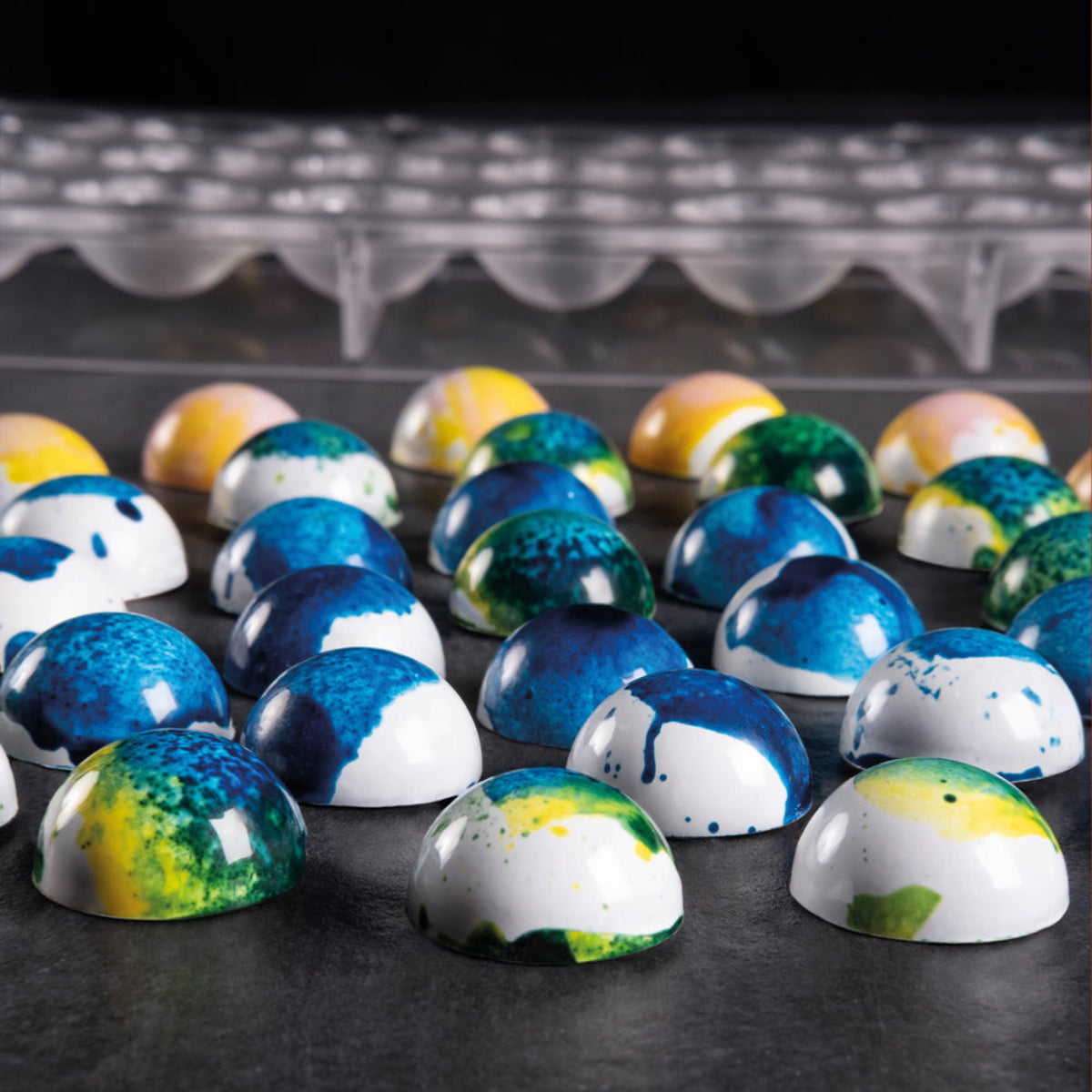

Using Colored Cocoa Butter

Pre-coloring mold cavities creates stunning designs. Warm cocoa butter colors to liquid consistency and paint designs into clean molds before adding chocolate. Create ombre effects, geometric patterns, or freehand artwork. For uniform coverage, professional spray equipment delivers exceptional results.

Apply light coats allowing each to crystallize before adding subsequent layers for depth and dimension. Combining different colors creates beautiful custom hues, while gold accents add luxury touches.

Metallic and Pearlescent Finishes

Metallized effects create luxury chocolate hearts perfect for weddings and upscale gifts. Metallic powders dusted onto set chocolate surfaces add shimmer, while pearlescent finishes provide romantic glow.

Apply metallic powders after demolding using soft brushes or mix with neutral alcohol and spray using airbrush equipment. Pearly Chocolate Grains in various colors pressed into chocolate before full crystallization create textured accents. These elements transform simple chocolate hearts into premium confections.

For velvet texture effects, specialized sprays create sophisticated matte finish. These varieties suit chocolate hearts perfectly, offering softer romantic presentation.

Adding Toppers and Embellishments

Enhance presentation with decorative elements. Pipe contrasting chocolate designs, add edible flowers, or position small chocolate curls. Our decorating combs and scrapers create textured patterns in chocolate before full crystallization.

Consider adding small messages piped in contrasting chocolate or pressing letter stamps into partially set chocolate. Gold leaf application creates ultra-luxe hearts perfect for special occasions. These finishing touches demonstrate attention to detail that elevates hearts from homemade to artisan quality.

Troubleshooting Common Issues

Understanding solutions to frequent challenges ensures consistent success across all production batches.

Chocolate Sticking to Molds

While silicone naturally resists sticking, improperly tempered chocolate or inadequate setting time causes hearts to adhere stubbornly. Ensure chocolate passes temper test before pouring into molds. Allow complete crystallization; premature demolding attempts damage chocolates even with flexible silicone.

If chocolates stick despite proper technique, place filled molds in refrigerator 10-15 minutes. Temperature shock causes rapid contraction usually releasing stubborn pieces. Flex mold gently rather than pulling chocolates directly.

Air Bubbles and Surface Defects

Trapped air creates unsightly holes in chocolate heart surfaces. Tap mold vigorously on counter immediately after filling, working air toward cavity openings. For detailed designs, use small brush pushing chocolate into intricate areas before tapping.

Chocolate that's too thick or cool traps air more readily. Maintain proper working temperature throughout molding. Thin chocolate flows into mold details better, releasing air naturally. Consider vibrating molds on specialized equipment for bubble-free professional results.

Dull or Streaky Finish

Bloom, moisture, or improper cooling creates dull streaky chocolate hearts. Fat bloom appears when chocolate warms and cools repeatedly causing cocoa butter separation. Sugar bloom occurs when moisture contacts chocolate dissolving sugar that recrystallizes as white spots.

Prevent bloom by maintaining consistent temperature during crystallization. Allow chocolate hearts to set completely at room temperature rather than refrigerating unnecessarily. Store finished pieces in cool, dry environment 60-65°F (15-18°C). Properly tempered chocolate resists bloom better than manually tempered alternatives. Learn more in our guide on how to avoid chocolate bloom.

Storage and Presentation

Optimal Storage Conditions

Store chocolate hearts in single layers separated by parchment paper in airtight containers. Maintain consistent temperature 60-65°F (15-18°C) with humidity below 50%. Avoid refrigeration unless absolutely necessary; temperature fluctuations cause condensation leading to bloom.

|

Storage Aspect |

Recommendation |

Duration |

Quality Impact |

|

Temperature |

60-65°F (15-18°C) |

Ongoing |

Prevents melting/bloom |

|

Humidity |

Below 50% |

Ongoing |

Avoids sugar bloom |

|

Container |

Airtight |

2-3 months |

Protects from odors |

|

Light Exposure |

Dark/minimal |

Ongoing |

Prevents fat oxidation |

Properly stored tempered chocolate hearts maintain quality 2-3 months. Compound chocolate lasts slightly longer due to vegetable oil stability. Label containers with production dates tracking freshness for quality control.

Creative Display Ideas

Present chocolate hearts using tiered displays, decorative boxes, or clear bags tied with ribbons. Our display options showcase chocolates while protecting from handling.

Arrange chocolate hearts in color-coordinated patterns or create ombre effects using various colored chocolates. Individual clear boxes allow recipients to appreciate decorative details without unwrapping. Add complementary elements like ribbons, dried flowers, or themed cards enhancing overall presentation.

Scaling Production for Events

Moving from small-batch production to event-scale requires workflow optimization and equipment investment.

Efficient Workflow Organization

Organize workspace systematically for efficient chocolate heart creation. Prepare all molds before tempering chocolate, ensuring clean polished surfaces ready for immediate use. Temper larger quantities maintaining working temperature longer using professional chocolate melters.

Work assembly-line style: fill all mold cavities, complete all scraping, allow all setting simultaneously rather than finishing individual molds sequentially. This approach maximizes efficiency while chocolate maintains optimal temperature. Multiple multi-cavity silicone molds enable substantial production volume with consistent quality.

Investment in Production Equipment

Quality equipment transforms production efficiency. Automated tempering machines eliminate manual variability, while cooling equipment maintains optimal crystallization temperatures. Professional spray equipment streamlines decoration for large batches.

Consider educational resources from master chocolatiers learning advanced techniques and design inspiration. Books covering chocolate work provide troubleshooting guidance and formula refinement that accelerates skill development.

Special Occasion Applications

Chocolate hearts suit various celebrations and events, with customization options matching specific themes and purposes.

Valentine's Day Production

Valentine's season drives peak demand for chocolate hearts. Plan production 2-3 weeks ahead accommodating order volume. Offer variety in sizes, flavors, and decoration styles appealing to different customer preferences. Classic red and pink dominate, but consider sophisticated options like dark chocolate with gold accents or ruby chocolate showcasing natural pink hue.

Package hearts in romantic presentations using red tissue, satin ribbons, and decorative boxes. Include message cards or custom labels personalizing gifts. Tiered pricing based on chocolate quality, decoration complexity, and packaging elaboration maximizes revenue opportunities.

Wedding and Anniversary Chocolates

Weddings and anniversaries require elegant chocolate hearts matching event sophistication. Coordinate chocolate colors with wedding themes using appropriate cocoa butter tints. White chocolate hearts decorated with edible gold or silver suit formal receptions, while milk chocolate with pastel decorations complement garden weddings.

Offer chocolate heart creations as favors, dessert table additions, or gift box contents. Custom stamping with initials or dates personalizes pieces. Professional packaging elevates perceived value justifying premium pricing for event chocolates.

Conclusion

Mastering chocolate hearts with silicone molds combines technical chocolate skills with creative design sensibility, producing romantic confections perfect for expressing affection year-round. Success requires understanding silicone's unique properties, executing proper chocolate preparation, and applying finishing techniques that transform simple ingredients into impressive gifts. Whether crafting Valentine's treats, wedding favors, or heartfelt everyday expressions, these methods provide a comprehensive foundation for heart chocolate excellence. Explore professional silicone molds, premium fine chocolate, and specialized decoration supplies at Zucchero Canada to create heart chocolates that captivate through both appearance and exceptional quality.

References

Greweling, P. (2023). Chocolates and confections: Formula, theory, and technique for the artisan confectioner (3rd ed.). John Wiley & Sons.

KREA Swiss. (2024). Professional food equipment and spray systems for chocolate artistry. https://kreaswiss.com/food-equipment

National Confectioners Association. (2024). Chocolate molding best practices and quality standards. NCA Technical Manual.

Pavoni Italia. (2024). Professional color collections for chocolate decoration. https://pavonitalia.com/en/collections/professional-collezioni-colori-e-materie-prime

Sutherland, J. P. (2023). Silicone bakeware: Properties and applications in confectionery. Food Technology Journal, 77(4), 45-52.

Laisser un commentaire

Tous les commentaires sont modérés avant d'être publiés.

Ce site est protégé par hCaptcha, et la Politique de confidentialité et les Conditions de service de hCaptcha s’appliquent.